Efficient warehouse operations resemble the work of a well-oiled machine, where every component must function precisely and without interruptions. To achieve this, it is worth taking care of the buffer zone in the warehouse, which acts as a mediator between different warehouse processes. Are you wondering what exactly a buffer zone is and why it is so important in a warehouse? In this article, you will find answers to these questions. And as a bonus, we have a few tips to help you use this area more effectively in your logistics.

What is a buffer zone in a warehouse?

The buffer zone in a warehouse is a designated space for the temporary storage of goods or materials between consecutive stages of warehouse processes. You can imagine it as a waiting room at a train station – a place where passengers wait for their connection. The buffer zone is designed to balance the pace between different logistics processes, which is why it is usually located near unloading, picking, or packing areas. It therefore acts as a logistical “cushion,” helping to avoid bottlenecks and improving the flow of goods.

Functions of a buffer zone in a warehouse

The main task of the buffer zone is to ensure operational fluidity and flexibility and to minimize the risk of downtime or bottlenecks in key warehouse areas caused by differences in performance between individual stages (e.g., between receiving goods and order picking, or between production and shipping).

A warehouse buffer serves many important functions. Among others:

- Temporary storage (“Waiting room”):

– serves as a place for short-term storage of goods/components awaiting further handling, e.g., before loading, quality control, repackaging, or entering the production line. - Flow continuity and bottleneck prevention:

– acts as a safety buffer, allowing goods to move smoothly between stages such as storage, picking, and shipping, preventing goods from accumulating and creating bottlenecks in high-traffic areas (e.g., receiving zone, picking zone). - Logistics flexibility:

– allows flexible management of the flow of goods, which is critical especially when:

the pace of deliveries does not match the pace of consumption (production),

there is demand variability,

processes have different efficiencies and require separation. - Allows the transport of materials from the warehouse to production lines in accordance with the “just in time” method.

- Ensuring process continuity:

Minimizes the risk of production or shipping downtime, protecting against delays in raw material deliveries or unforeseen internal issues.

The role of the buffer zone in warehouse efficiency

A well-organized buffer zone significantly enhances the efficiency of the entire warehouse facility. It acts as a safety valve in cases of fluctuating demand, delivery delays, or seasonal peaks. Additionally, the buffer zone helps optimize truck unloading times, as goods can be quickly moved from the receiving area to the buffer, freeing up space for incoming shipments. Automation systems in the buffer zone streamline processes such as labeling, quality control, and preparing products for further transport.

A key role in this process is played by the Explitia Production Portal module, which is responsible for managing production buffers. This WMS-class solution enables real-time monitoring of buffer occupancy levels.

Applications of the buffer zone

The role of the buffer zone cannot be overstated. This space plays important functions in the following places:

- In production warehouses

Pre-production buffer – as a buffer for raw materials and components awaiting delivery to the production line (WIP, work in process).

Post-production buffer – as a “waiting room” for finished products awaiting quality control or transfer to the shipping zone.

- In distribution and shipping centers

As a staging area – completed orders are temporarily stored and grouped here to ensure continuity and speed of deliveries.

- In e-commerce and reverse logistics

The returns and complaints buffer is a designated space for the temporary storage of goods returned by customers, enabling faster handling (e.g., condition check, re-stocking, refund).

How to optimize a buffer zone in a warehouse

To fully utilize the potential of a buffer zone, it is essential to implement warehouse space management software.

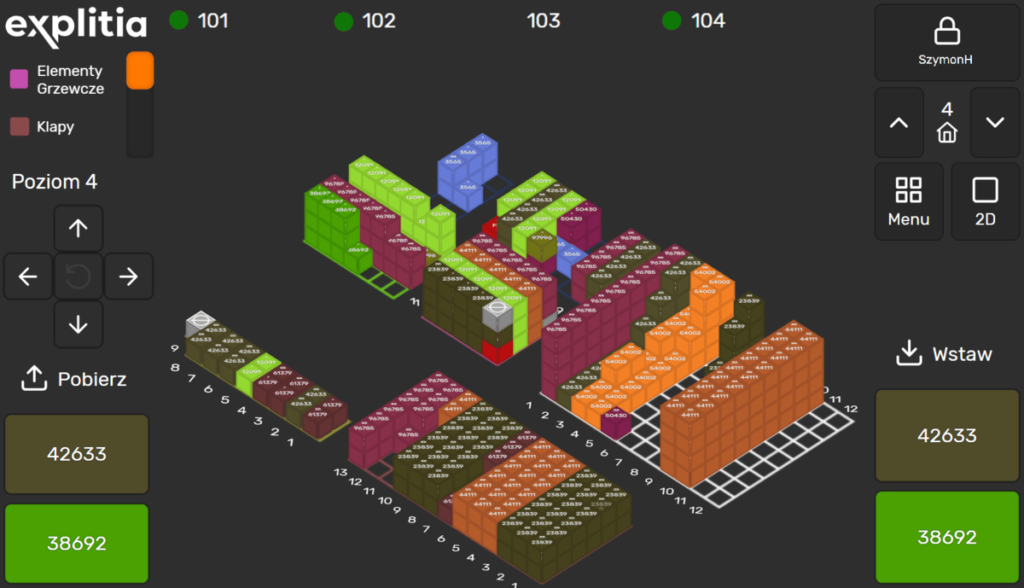

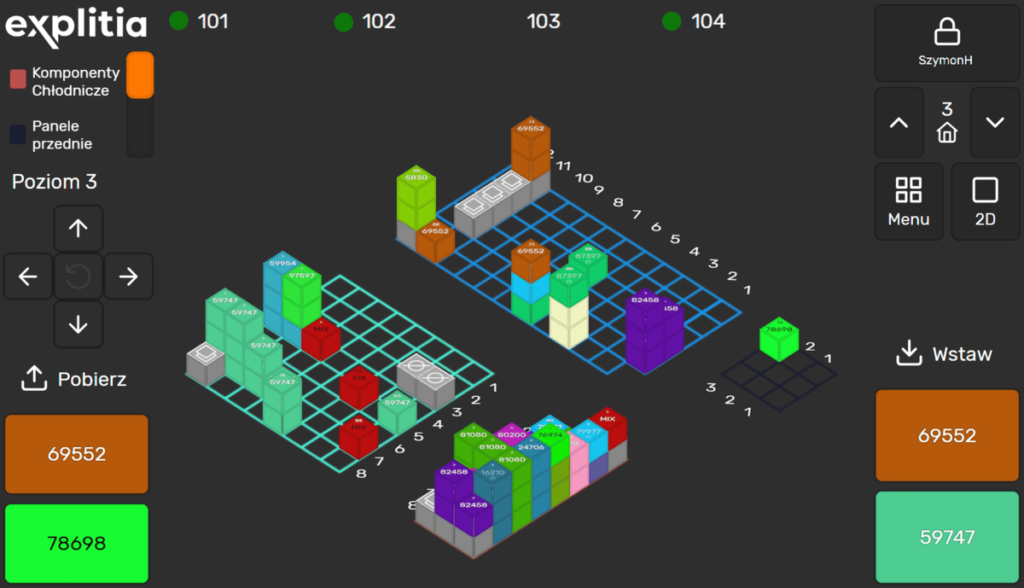

This is where Explitia comes in. As part of the Production Portal, its advanced buffer management system provides full control over goods allocation and flow. It allows you to:

• Design warehouse layouts, optimizing component placement based on FIFO or LIFO strategies. The system automatically analyzes platform distribution and selects optimal storage locations, considering platform sizes, load weights, and predefined rules (e.g., grouping components in a single channel).

• Efficiently locate goods and platforms, thanks to real-time inventory tracking and fast filtering.

• Generate inventory reports, user activity logs, and detailed platform summaries, supporting effective buffer management.

• Visualize the warehouse buffer zone in a clear and user-friendly way with different viewing options.

• Integrate warehouse data with ERP and MES systems.

In short, automation enables dynamic buffer size adjustments to current needs and real-time monitoring of goods flow.

An important factor in optimization is also the strategic location of the buffer zone – it should be easily accessible from both the receiving and dispatch areas. Dividing the buffer into sectors based on product types or operational needs further boosts efficiency. Additionally, ensuring safety through clearly marked storage and transport zones is crucial.

A well-managed buffer zone is the foundation of seamless warehouse operations. It allows for flexible workload management, improves logistics processes, and contributes to the smooth operation of the entire supply chain. Keep in mind that proper use of this space can significantly enhance your warehouse’s efficiency.

That’s why investing in automation and digital management systems, such as MES, EMS, or WMS, is a smart move. Digital transformation will ultimately lead to greater efficiency and productivity in logistics processes.

Would you like to learn more about warehouse buffer zones? Not sure how to bring your industry to the 4.0 level? Write to us, and we’ll gladly answer all your questions and clear up any doubts you may have.

Gain knowledge to stay ahead of the competition! Read the explitia blog