Optimum production plan

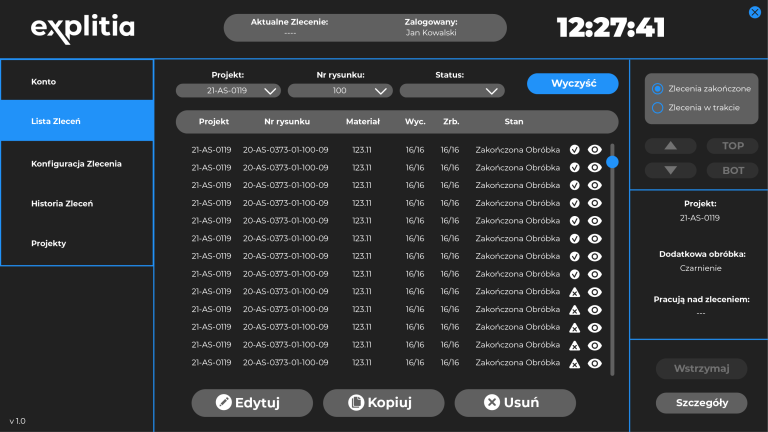

By using the solution, the technologist creates production orders with a constant access to them. He/She can edit orders and, if necessary, delete them or suspend the work of the operator. The information about the order is transferred automatically, which considerably facilitates and speeds up the work.

Order scheduling

Priorities can be assigned in two ways – the technologist can set a hierarchy, or the operator can determine the order based on the created orders (taking into account the information about the material, number of pieces, etc.).

Detailed data from the production process

When starting work, the operator runs the order with one click and informs about the completion in the same way. Detailed information about the completed order (dimensions, quantity, cut-outs, OK/NOK number) is available in the technologist’s and administrator’s panel in real time.

Why is it worth it?

| Integrated planning with the warehouse - better use of warehouse resources. |

| Possibility of integration with other systems, e.g. ERP - making business decisions based on reliable data. |

| Possibility of linking the system with the BOM. |

| Automation of manual production planning and reporting. |

| Current information about the progress in the implementation of the plan - the actual production counter. |

| Access to detailed information on the parameters of manufactured elements and used materials, e.g. bottles, metals, labels, boxes. |

| Optimum production plan - increased efficiency. |

| Smooth communication between planners and operators - faster responses and greater production flexibility. |

| Constant access to current and archived data. |

| Scalability of the solution - the module can be implemented as a standalone system or in connection with other tools of the Production Portal. |

Contact us

Do you want to move your production plant to level 4.0? Are you interested in modern solutions for industry in the field of automation and digitisation? Be sure to let us know!