What is an MES system and how does it optimize production processes?

An MES (Manufacturing Execution System) is an advanced production management system that integrates all aspects of the manufacturing process. Simply put, MES gives you full control over production. How? It’s a powerful tool that covers key processes such as modeling and optimizing production workflows, including:

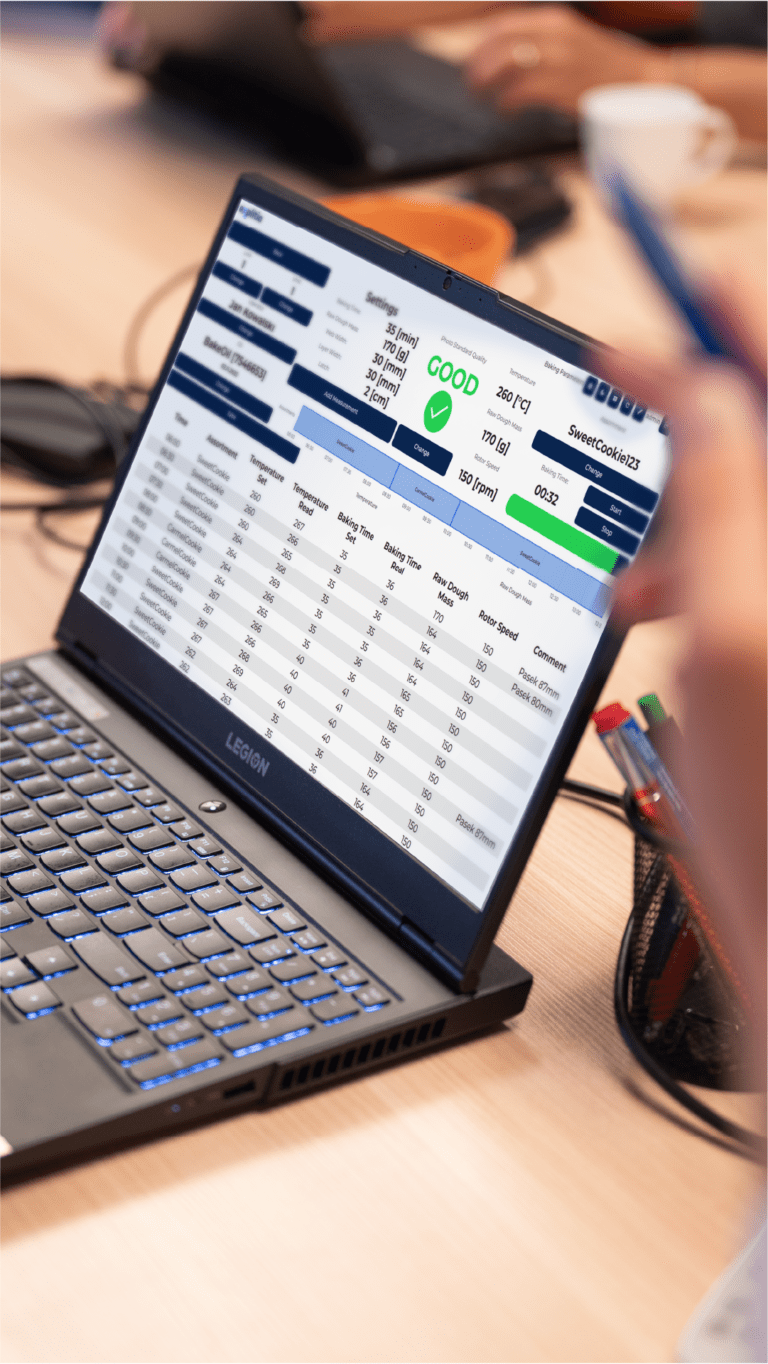

MES-class systems, such as Explitia’s Production Portal, integrate with devices and other systems in the plant, providing real-time data. With their help, your company can optimize production processes by closely monitoring and controlling every stage of manufacturing. They also contribute to increased efficiency, cost reduction, and improved product quality.

What is the Production Portal?

A comprehensive and scalable MES (Manufacturing Execution System) solution, featuring modules such as planning and scheduling, OEE, data collection and visualization, operator instructions, statistical process control, reporting, and traceability. This advanced system allows for the implementation of one or multiple modules, tailored to your production needs.

Contact us

Do you want to move your production plant to level 4.0? Are you interested in modern solutions for industry in the field of automation and digitisation? Be sure to let us know!

Increase production efficiency with an MES system

explitia’s Production Portal is more than just MES software—it’s a comprehensive tool for companies looking to elevate their production management. By implementing an MES system, you gain full control over the manufacturing process and leverage advanced optimization methods.

Here are the key areas where explitia’s Production Portal stands out as an MES traceability system:

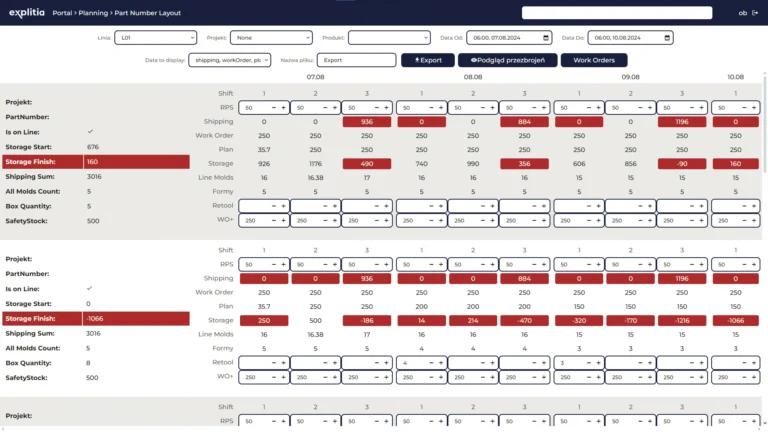

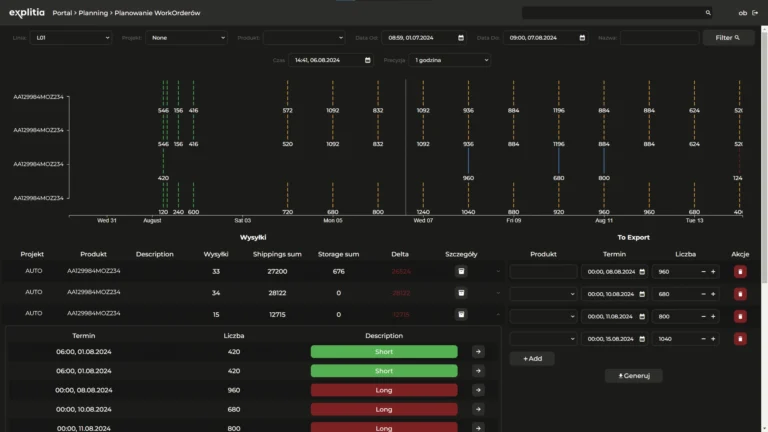

Production planning and scheduling

What should be produced, and in what order, to optimize inventory usage, increase efficiency, reduce cycle times, and save operator working hours?

Discover advanced algorithms that enable better task distribution and smarter resource management—both human and material. With explitia’s Production Portal, you can forget about wasted raw materials, lost working hours, and unnecessary machine wear.

Data collection and visualization

An advanced IT tool designed for monitoring, analyzing, and managing production and operational data. It enables:

- Real-time monitoring of measurements and operational parameters from various machines and devices,

- Historical data analysis,

- Automatic alert notifications,

- Visualization of production shifts and monitoring of raw material availability.

The system also provides an operator panel, allowing direct machine and equipment control as well as real-time adjustments. The module includes electronic forms for recording production data and quality documentation.

Using an MES software system for data collection and analysis helps identify bottlenecks and implement necessary improvements—giving you greater control over your production processes.

Real-time monitoring

The production status visualization system automatically and continuously provides information on the current stage of the manufacturing process. This enables real-time data monitoring and supports business decision-making, such as process optimization or adjustments to the production plan.

Precise analysis of machine and operator efficiency, along with tracking key performance indicators (OEE), allows you to continuously assess production performance and respond effectively.

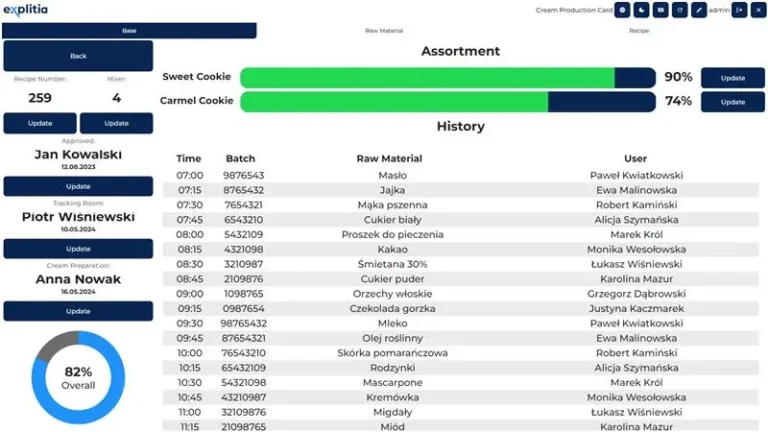

Traceability

The Production Portal gives you complete traceability of processes, enabling in-depth analysis and optimization of manufacturing and service operations. How does it work? With this solution, you can reconstruct the full genealogy of your products, access detailed information about raw materials, batches, and processes that contributed to the final product.

Leverage precise insights into your production to enhance competitiveness and ensure safety. Manage manufacturing with the flexibility to adapt and grow—even in an ever-evolving environment.

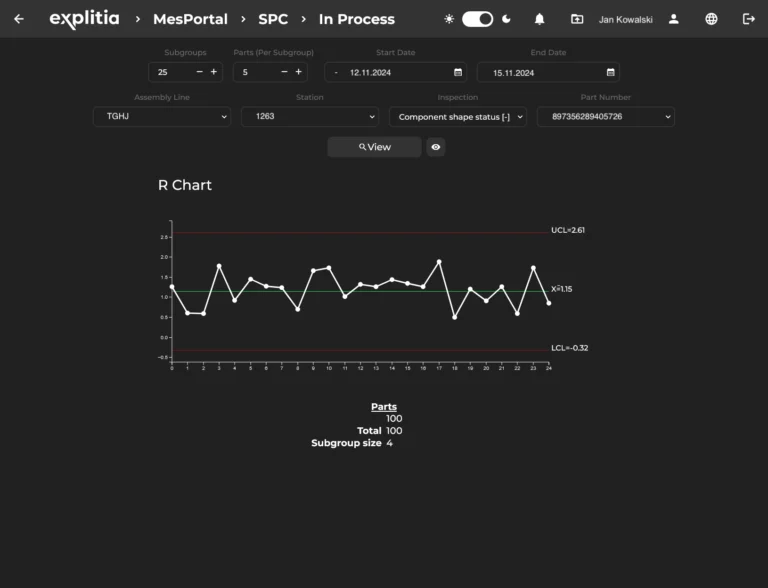

Statistical Process Control

The module continuously collects data from production processes and analyzes it with advanced statistical tools. It detects deviations before they turn into real issues and quickly pinpoints the source of errors.

Interactive operator instructions

An intuitive solution that supports operators in manual workstations by ensuring process consistency. It also enables data collection from manual and semi-automated production stations.

MES and ERP integration

The MES system integrates seamlessly with other enterprise systems, such as ERP, enhancing production efficiency and business management. Manufacturing data is automatically recorded in the management system, ensuring smooth and accurate operations.

explitia – 6 steps to implementing an MES system in your enterprise

We are experts in manufacturing digitization. With Explitia, you know exactly what you’re getting—no surprises. When you work with us, our team will guide you step by step through the MES implementation process. Here are the six stages we’ll go through together:

1 - Discovery Call

An initial consultation to understand your company’s needs and industry specifics.

2 - Workshop

3 - Budget proposal

Preparation of a preliminary implementation cost estimate.

4 - Pre-implementation audit

Detailed identification of technical challenges.

5 - Pilot project

Testing selected modules of the production management system on a small scale.

6 - Full-scale implementation

Comprehensive system deployment with integration into the existing IT infrastructure.

That’s not all—we won’t leave you on your own! explitia provides training for your employees and post-implementation support, including technical assistance and flexible service packages tailored to your needs.

With our expertise and experience, MES implementation in your production facility will be smooth and hassle-free.

Which industries benefit the most from MES implementation?

Manufacturing Execution Systems (MES) are widely used across various sectors, especially those where automation and process optimization are crucial. These industries include:

automotive industry

Production line automation enhances the efficiency of managing high-volume manufacturing and improves product traceability.

food industry

In this industry, quality monitoring, traceability, and compliance with standards are essential.

chemical industry

electronics and home appliances industry

Each of these industries, by implementing modern MES systems, improves its chances of increasing efficiency, enhancing product quality, and reducing costs—in short, optimizing production.

MES – no more downtime and better production efficiency

Do you know how much time your team spends searching for the causes of downtime? The explitia Production Portal monitors processes in real time, identifying potential failures before they happen and enabling quick responses to issues.

Additionally, the MES system helps with:

- Planning preventive maintenance

- Automating notifications for maintenance teams

- Optimizing resource allocation and improving schedule management

Optimization as a straightforward path to Industry 4.0

Process optimization is crucial in modern industry due to increasing competition and evolving customer demands. Efficient process management enables:

- Higher efficiency – better resource management and automation of repetitive tasks lead to greater productivity.

- Lower operational costs – optimization helps reduce waste and unplanned downtime.

- Improved product quality – effective quality monitoring results in fewer defective products.

- Shorter order fulfillment times.

What production data does an MES system analyze, and how does it benefit your business?

The explitia Production Portal was created to give your team access to essential production data, including:

- Line efficiency (OEE) – evaluates the actual performance of machines.

- Production cycle time – helps identify areas for improvement.

- Alarms and downtime causes – enable quick problem resolution.

- Machine performance – assesses equipment efficiency and supports maintenance planning.

- Product quality – monitoring quality indicators allows for rapid response to issues.

Analyzing this data empowers your business to make better decisions, plan investments more wisely, and drive sustainable production growth.

Why is it worth it?

| Flexible and agile production | With real-time data, you can make business decisions more efficiently and effectively in a changing environment. Production history allows for quick product recalls in case of defects, ensuring quality and compliance. |

| Complete product knowledge | You gain access to all parameters related to a product's manufacturing process based on its serial number (individual item ID). |

| Compliance with Lean Manufacturing Principles | Automatic data collection from the production process enhances transparency. It enables data-driven insights, continuous improvement, and ongoing optimization of manufacturing processes. |

| Improved communication | Real-time automatic order flow—from planner to operator. You also gain detailed insights into order progress and the produced component. |

| Lower costs | Continuous access to real-time and historical data, with the ability to analyze results in specific contexts (e.g., machine, operator, or department). Automated data flow reduces manual entry and eliminates redundant information across multiple systems. |

| Real-time process control | Checking at each stage whether a part can proceed in production significantly enhances manufacturing safety. |

| Enhanced safety | Real-time monitoring with automatic or semi-automatic analysis. Detect deviations early—before they turn into actual problems. |

| Error elimination | Automatic reporting and data logging into the ERP system minimize errors that could occur with manual data entry. Additionally, system integration prevents unnecessary data duplication. |

| Better workforce management | Process automation frees up employees from manual paperwork, allowing them to focus on creating real value. |

| Increased productivity | The ability to quickly identify bottlenecks and improve communication enables optimal production planning and process enhancement, leading to increased efficiency and higher productivity. |

Production Portal – Watch sample recordings

The Production Portal is made for you!

Select the modules that bring the most value to your business and gain real-time insights into your machinery. Stay informed and optimize your production processes efficiently.

Write to us

Are you looking for IT systems for your machine park? Do you want to digitize your plant? Make an appointment for a free consultation!