Traceability from manual and semi-automatic machines

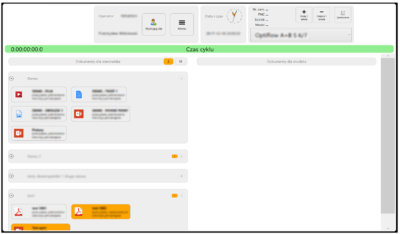

Solution supports the creation of a production genealogy for products manufactured on manual and non-automatic stations. The operator goes through the next steps of the operator’s instruction, and at that time the system collects statistics from the action. Quantity, quality, testing and cycle time data are collected. Information is collected automatically during the process, not burdening the operator with time.

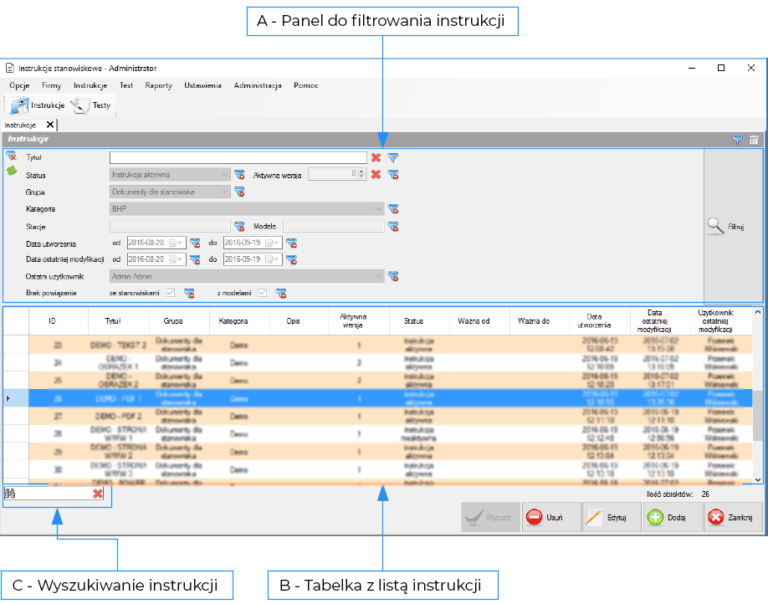

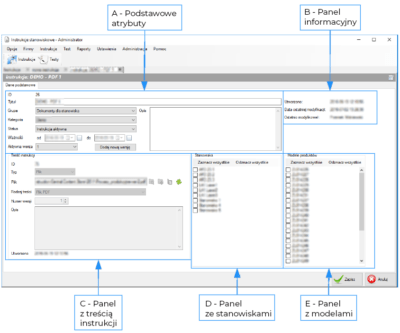

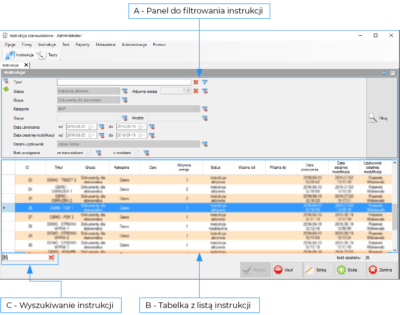

Operator’s workstation instruction

Solution is a part of the Production Portal. It is responsible for providing operators with clear instructions. The employee goes through the panels step by step. With this solution, repeatability of performed actions is guaranteed. The tool also accelerates the onboarding of a new employee and supports production continuity – when an employee is changed during the process, the operator goes through the next stage and does not have to start from the beginning.

Why is it worth it?

| A way to traceability for manual and non-automatic workstations. |

| Optimisation of the production process - with access to reliable data. |

| Guaranteeing the repeatability of performing operations on manual stations. |

| More efficient communication with the production department - for example, transferring important information to machine and station operators. |

| Better flow of information about the progress of work, taking into account the time of a given cycle and efficiency parameters. |

| Better flow of information about the progress of work, taking into account the time of a given cycle and efficiency parameters. |

| Increased safety - instruction on how to work safely. |

| Scalability of the solution - the module can be implemented as a standalone system or in connection with other tools of the Production Portal. |

Contact us

Do you want to move your production plant to level 4.0? Are you interested in modern solutions for industry in the field of automation and digitisation? Be sure to let us know!