What are MES systems?

MES (Manufacturing Execution Systems) are essential tools for managing and monitoring production in real time. They connect the world of automation (SCADA) with business management (ERP), creating a unified environment for controlling and optimizing manufacturing processes.

While SCADA handles direct machine control, and ERP focuses on planning, finances, and logistics, MES operates where value is created – on the production floor.

MES systems collect real-time data and give you full control over the entire production process.

The concept of MES emerged in 1992 and has since evolved significantly. Today, MES systems vary depending on the industry and plant size, but their goal remains the same: increase control, transparency, and production efficiency.

MES systems – automating data flow

Many plants implemented MES years ago based on past needs, technologies, and limited integration options. These legacy systems often lack direct machine connectivity, leading to manual data entry and lack of standardization.

At explitia, we specialize in modernizing such environments. We automatically collect data from production lines and machines (PLC, SCADA, sensors), eliminating the need for manual reporting. As a result, you:

• increase data accuracy,

• reduce response times to issues,

• minimize human errors and operational costs,

• build a solid foundation for analytics and production optimization.

Your MES can run faster, more accurately, and with zero downtime – even if it was implemented a decade ago.

MES system features

An MES system is more than a production logging tool – it’s the command center for your manufacturing process. Key features include:

| Production operation tracking | step by step, linked to orders, employees, and machines. |

| Performance monitoring (OEE) | tracking uptime, downtimes, breakdowns, and micro-stoppages. |

| Personnel and access management | monitoring presence, qualifications, and operator authorizations. |

| Traceability | full tracking of batches, materials, and process parameters. |

| Operational documentation management | digital workflow of instructions, production plans, and checklists. |

| Device and sensor integration | automated data collection from machines. |

| Reporting and analytics | generating reports for managers, quality departments, and executives. |

Benefits of implementing MES

MES is an investment that pays off quickly – both operationally and strategically. By automating and organizing information flow in production, you gain:

Full real-time production control – know what’s happening on the shop floor without manual data gathering.

Faster, more accurate decision-making – access to up-to-date information enables rapid responses.

Increased operational efficiency – reduce downtimes, boost machine and labor utilization.

Improved quality and traceability – every operation is logged, making error detection and compliance easier.

Reliable data for business decisions – management can act based on facts, not assumptions.

Shorter order fulfillment times – fewer errors, fewer bottlenecks, smoother planning.

Better audit and certification readiness – the system supports compliance with standards like ISO, AQAP, and TISAX.

Who needs a MES system?

MES systems are essential for manufacturing companies seeking full control over how their products are made. They’re especially valuable for:

- Industrial plants with batch or custom production aiming to improve efficiency and quality.

- Companies in regulated environments (e.g., defense, medical, food), facing strict reporting and traceability.

- Manufacturers with extensive technical documentation needing data flow automation.

- Organizations investing in digital transformation, planning to integrate production data with ERP and business analytics.

Integration with ERP and SCADA

MES works best when integrated with your other systems:

With ERP (e.g., SAP, Microsoft Dynamics, Comarch, IFS): synchronize production orders, materials, BOMs, and execution statuses. MES automates operation confirmations and feedback to ERP.

With SCADA and automation: MES collects data directly from machines, PLCs, sensors, and visualization systems. This eliminates human error and ensures data reliability.

A well-integrated MES is the backbone of seamless information flow – from the shop floor to the boardroom.

Independent consulting and tailored MES implementations

As independent technology advisors, we don’t sell a single solution – we recommend the best one. Based on process analysis and your production needs, we help determine whether to go with a market-proven MES, expand your existing system, or build a custom solution.

Not sure where to start your factory's digital transformation?

Get in touch with explitia for technology consulting.

MES from global vendors – AVEVA, COPA-DATA, and more

We implement and integrate MES systems from leading providers such as AVEVA, COPA-DATA, and Siemens. With years of hands-on experience in AVEVA solutions, we can precisely adapt the system to your production environment. We work with open standards so you can integrate MES with ERP, SCADA, and other OT/IT tools.

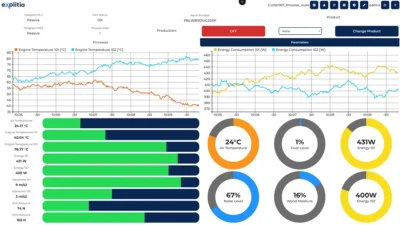

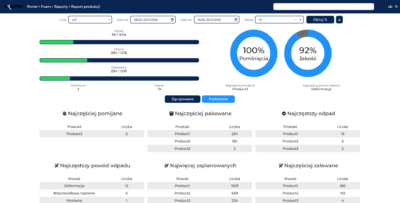

explitia Production Portal – MES that grows with your business

For clients seeking flexible MES-class solutions, we offer our proprietary software – the Production Portal. This scalable system allows you to monitor production, report data, manage traceability, and respond in real time.

You can develop it modularly – from basic logging functions to advanced performance analysis (e.g., OEE). The system is built for harsh industrial environments, is intuitive, and ready for the shop floor.

Custom MES-class software – when off-the-shelf isn’t enough

Not every production line fits a standard template. If your processes are unique, require special integration, or need to operate in challenging conditions – we can build a tailored MES solution for you.

We design from the ground up – considering processes, infrastructure, and users. We combine IT, OT, and UX/UI competencies to deliver a solution that works and delivers real results.