OEE (Overall Equipment Effectiveness) is primarily associated with measuring machine efficiency, but it is also a tool for improving communication within the company and optimizing production. In practice, its impact goes far beyond the production floor – it changes the way employees, leaders, and entire departments communicate. Surprising? See how, thanks to implementing OEE combined with real-time monitoring systems, the flow of information in your company can become faster and more transparent, and how it can also help you reduce the number of conflicts.

OEE in a nutshell

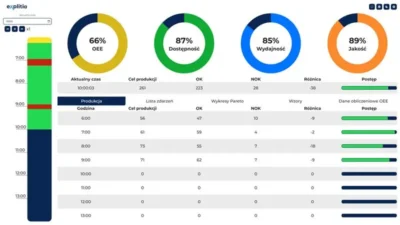

Before we focus on how OEE changes communication within a company, let’s pause to consider what OEE actually is. The acronym stands for Overall Equipment Effectiveness. In short, it is a measure of the efficiency of machines or production lines in a company. It shows how much a given machine works compared to its maximum theoretical potential. OEE consists of three values:

- Availability – what percentage of available time the machine actually worked.

- Performance – how much was produced compared to the theoretical rate.

- Quality – what percentage of production meets requirements.

But beware: without context these values are just numbers.

100 pieces per shift can be a success or a disaster. An OEE of 85% on a line producing one type of part is a completely different result than 85% with 15 different variants and changeovers every 2 hours.

That’s why context is so important, namely:

- what the actual cycle time is (not just the theoretical one),

- how many planned changeovers occur during the shift,

- what quality of raw material you feed into the line,

- what condition the machine is in.

Only then does the OEE indicator become a management tool rather than an empty statistic.

How to interpret OEE value

For a production efficiency metric to support optimization across different departments in a company, one must understand how to interpret different OEE levels:

| OEE Level | Interpretation | What It Means in Practice |

| 85% and above | Mastery | Production operates with almost no losses – rarely seen in real conditions, requires excellent organization and a culture of continuous improvement. |

| 60–84% | Good level | Machines are well utilized, but there is still room for improvement – e.g. eliminating short stoppages or reducing waste. |

| 40–59% | Medium level | Losses are noticeable – frequent breakdowns, slower operation than planned, significant scrap. Requires corrective actions. |

| Below 40% | Low level | Major problems with availability, performance, or quality – equipment and processes require thorough analysis and reorganization. |

Interestingly, many companies think they have a “good” result when it is around 60–70%, but in industries with high competition and low margins, even a 5% increase in OEE can significantly improve profitability.

How OEE improves communication in a company

When every department – production, maintenance, logistics, planning – uses the same data, the problem of different interpretations disappears. OEE provides an objective point of reference.

How does this look in practice? In the traditional model, employees from different departments called each other to say, for example: “We’re done, come pick up the product.” Meanwhile, in the OEE system model:

- the warehouse sees when to deliver materials,

- the quality department knows when to conduct tests,

- logistics plans the pickup of the finished product,

- maintenance monitors all machines on one screen.

The result? Discussions based on data rather than assumptions, elimination of communication delays, and better use of resources.

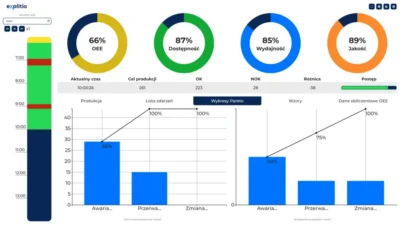

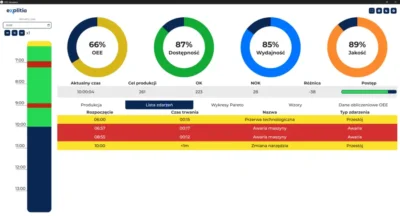

Dashboard – the information hub for the whole company

Implementing a tool such as the explitia Production Portal makes OEE indicators visible in real time. Each department can filter data by line, shift, or operator.

On scoreboards (also visible on the shop floor), the current production status is displayed. Such visualization of production status enables immediate response in case of deviations.

Side effect of OEE: increased trust

Data transparency changes organizational culture. Instead of asking “Who’s to blame?”, managers motivate employees to reflect on what can be improved.

One of explitia’s clients noticed that after implementing OEE, disputes between shifts disappeared – because everyone saw the same numbers, and numbers – as we know – don’t lie.

OEE is not just a number in a report – it is a tool that integrates communication within the company. Thanks to common indicators and transparent dashboards, different departments start speaking the same language, and decisions are made faster and more accurately.

Read the explitia blog