What is traceability?

Traceability (traceability, production genealogy) means collecting key data from the production process and all stages of the supply chain. Full traceability means detailed knowledge of the product and verification of its path based on various sources of information. In industry, it means full transparency and traceability of the history and related parameters – from the raw material to the finished product delivered to the store shelf.

Automotive traceability — what data is collected

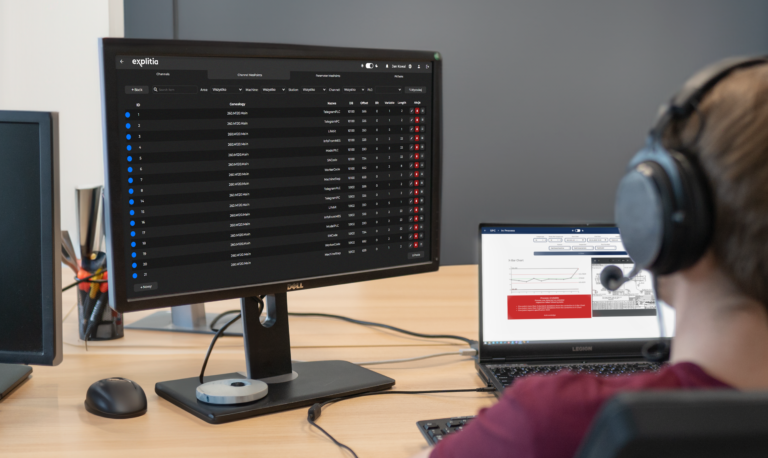

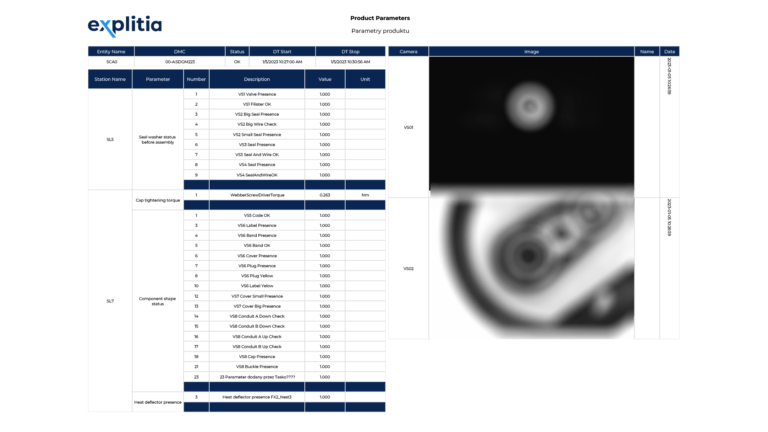

The production genealogy system allows (in real time) to collect and combine data from many sources, giving e.g. the information on:

- What components was the product made of?

- What semi-finished products are included in the finished product.

- From what supplier, what batch of materials the raw materials come from.

- On what machines and under what conditions the components were produced.

- Where and when the item was produced.

- Which employees were involved in the production process.

- Who bought a given product or a given production batch.

Why is it worth it?

| Automatic data collection from the production process. |

| Manufacturing history, which enables, for example, to quickly withdraw a defective product from the market. |

| Statistical control of industrial processes. |

| Reducing the costs associated with completing manual documentation. |

| Automated posting to ERP systems - connecting production systems with business software. |

| Full insight into current and archival data and the possibility of more efficient analysis. |

| Making the right decisions faster, based on reliable data. |

| Ability to access all parameters related to the production of a given product based on its serial number (individual element ID). |

| Meeting more and more detailed customer’s requirements. |

| Scalability of the solution - the module can be implemented as a standalone system or in connection with other tools of the Production Portal. |

Contact us

Do you want to move your production plant to level 4.0? Are you interested in modern solutions for industry in the field of automation and digitisation? Be sure to let us know!