Production Report - technology

The production report contains a range of information presented in a visual and efficient form for analysis. Production reports are based on e.g. on: Microsoft Power BI or Microsoft SQL Server. However, it is not only the data, but their appropriate context in relation to a specific machine, operator or process that allows an effective response.

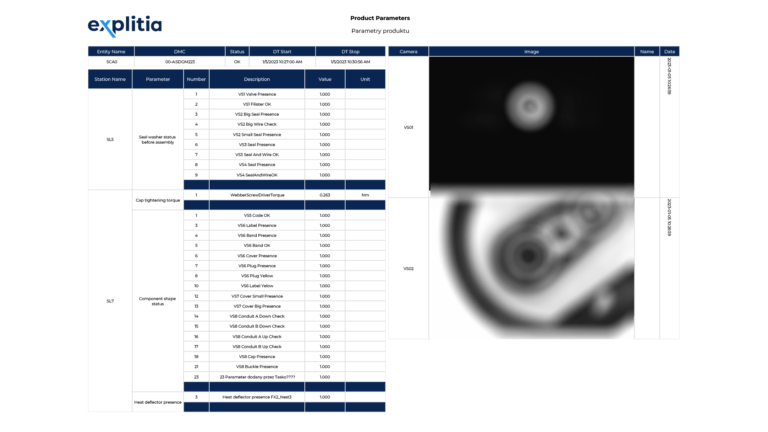

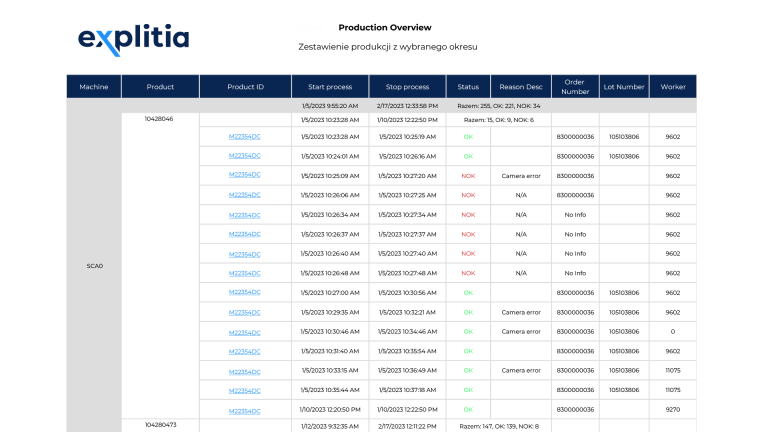

The production report shows a full genealogy of production, starting from the most important overview (overview of production for the whole day) to detailed data on a specific order, machine and product. Based on the data, it shows important indicators.

Production report - what does it include?

Supervision of the production process thanks to integration with ERP

Automated production reporting and access to a range of data can be quite a challenge for managers and leaders. Detailed data should be given an appropriate context. The solutions of the Production Portal make it possible to define such elements as the context of the machine or the operator. Integration with the ERP system allows an automatic transfer of all information relevant from the point of view of production management, e.g. such as:

- number of manufactured items that meet the requirements,

- causes of errors detected in the manufacturing process,

- reasons for downtime,

- current state of the machine,

- start and end time of production of a given batch,

- consumption of energy carriers in relation to a given machine.

And much more, where the limit is our imagination and the capabilities of the production machine itself. Therefore, it is much easier to draw conclusions, for example regarding production planning, purchase of a new machine or planned maintenance.

SPC production report

With the SPC solution, the conclusions for the future can be drawn much more efficiently. In this way, it is possible to check whether certain statistical indicators are within the tolerance limits.

The report is the result of the work of the advanced statistical production control module. It shows not only the history of production, but above all – during the production process it can stop it if the set threshold values are exceeded.

Reports are generated automatically and can be sent by e-mail. A glance is therefore enough to be able to react.

Why is it worth it?

| Efficient access to data supporting production management. |

| Better management of human resources - reducing the costs associated with completing paper documentation and the time needed to find the necessary information. |

| A way to standardise communication and information exchange within the company. |

| Statistical process control. |

| Automatic production reporting eliminates the need to complete the reports manually, and thus - guarantees the correctness of the data. |

| Greater security - constant insight into data from the production process. |

| Scalability of the solution - the module can be implemented as a standalone system or in connection with other tools of the Production Portal. |

| Ability to automate dedicated reports in communication with the client. |

| The response to the requirements of end customers. |

Contact us

Do you want to move your production plant to level 4.0? Are you interested in modern solutions for industry in the field of automation and digitisation? Be sure to let us know!

Looking for reliable insights? Read the explitia blog.