Key Challenges in the Automotive Industry – Solutions by explitia

1. Optimization of data flow from the production plan

The EINGABE application (initial station) offers:

- Production according to a set plan (possibility to integrate ERP system data retrieval);

- Dynamic retrieval and transfer of recipes (production programs) to the automation layer;

- Reduction of errors caused by manual production planning.

2. Traceability – full product identification

With the ERFASSUNG application (final station), you can:

- Collect and archive traceability data stored on RFID carriers;

- Verify production parameters and perform final product quality control;

- Analyze DMC component compliance with quality certificates;

- Export data to central reporting portals (compliant with VW standards).

3. Repair and diagnosis at rework atations

The REP application allows for:

- Verification and correction of data for products requiring rework;

- Synchronization of information between EINGABE and ERFASSUNG, ensuring full traceability even for repaired products;

- Verification of certification compliance after repairs.

4. Flexible diagnostic and testing tools

With the READER application and TEST STATION functions, you can:

- Read data from RFID carriers at any point on the production line (using mobile heads);

- Perform fast inventory checks and verify production station functionality;

- Automatically save and analyze test station results, independently of the main traceability system.

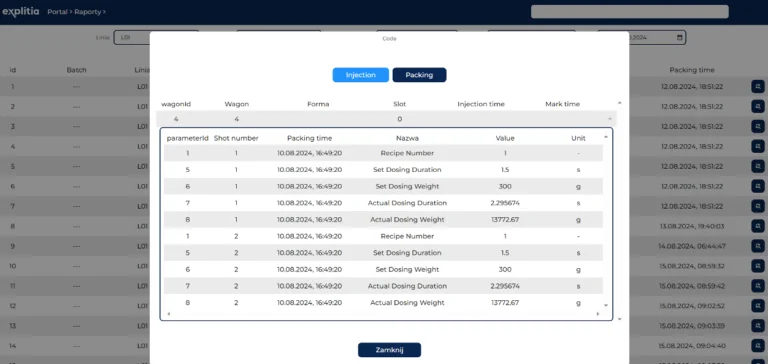

5. Central reporting and data analysis

The REPORTING PORTAL is an innovative solution that optimizes production reporting. It enables:

- Real-time data synchronization from all applications;

- Historical data archiving for audit and quality analysis purposes;

- Generating reports in compliance with global automotive industry standards;

- Integration with quality management and logistics systems.

Why Implement explitia’s solutions in your production plant?

Industry expertise

The explitia team has extensive experience, proven by successful implementations at Volkswagen Polkowice and in-depth knowledge of VW group standards, including TRV, TISAX, and reporting portal systems.

Full Traceability

With explitia, you get guaranteed quality certification compliance and simplified audits.

Scalability

We offer gradual expansion of system functionalities based on your plant’s needs.

Flexible implementation

The modular architecture of explitia’s systems allows for quick adaptation to different plants and standards (e.g., BMW, Skoda, Audi).

Process optimization

Automation of data flow between the business layer and the automation layer.

Our experience with Volkswagen Polkowice

- Development and implementation of the EINGABE, ERFASSUNG, REP, and READER applications.

- Integration with central reporting portals according to global standards.

- Product certification development and DMC control for full compliance with environmental protection requirements.

- Integration with PLC systems and modern test stations.

With our expert knowledge and extensive experience, explitia is ready to support other production plants, offering proven and flexible solutions.