What is a Digital Product Passport

The Digital Product Passport is a detailed, digital record that allows for tracking and monitoring the product lifecycle. It collects data about various stages of production, processing, and distribution, enabling consumers to better understand the origin of raw materials, production dates, quality parameters, ecological aspects of production, and quality certifications.

Digital Product Passport – definition

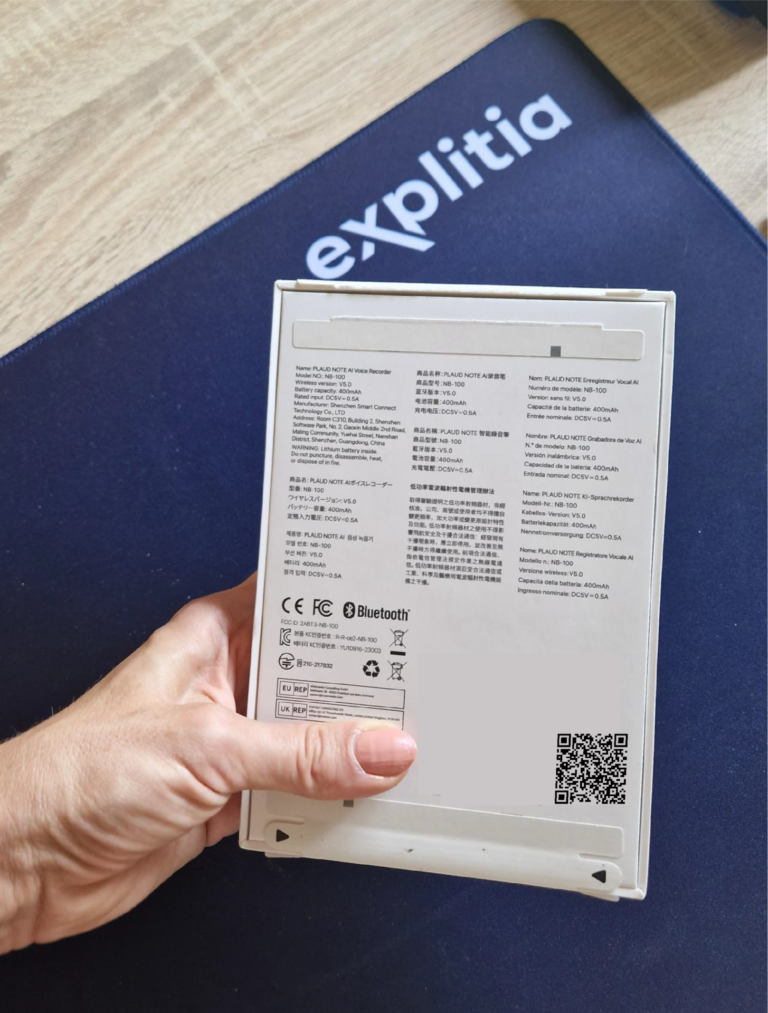

The Digital Product Passport is essentially a product’s „ID number”. It is a unique identifier that ensures full traceability of every item. The information included in a DPP is encoded in a QR code that, once scanned, provides access to detailed product data. Sharing this data not only enhances a company’s transparency but also builds consumer trust. The more specific the data encoded in the product’s QR code, the greater the brand’s credibility.

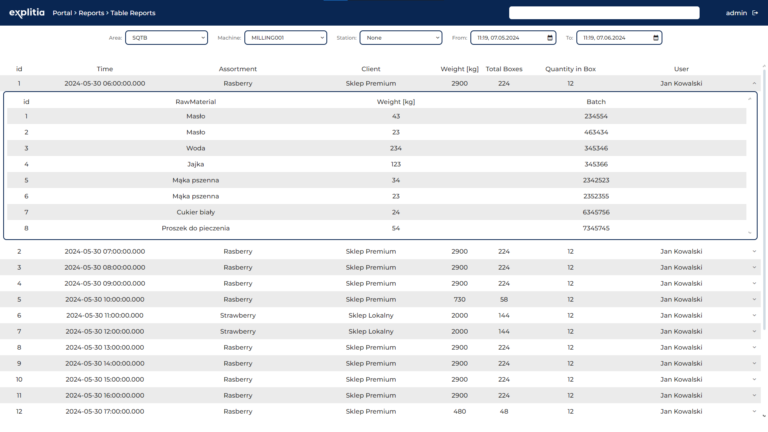

Digital Product Passport – example data

Contact us

Do you want to elevate your manufacturing plant to Industry 4.0? Are you interested in modern automation and digitalization solutions for the industrial sector? Be sure to reach out to us!

The importance of product traceability

Product traceability involves tracking every component or finished product across all stages of the manufacturing process – from raw materials entering the plant to final packaging.

Digital Product Passport and traceability

A traceability system is an advanced tool that automatically collects data from every stage of production. It enables monitoring and analysis of all processes – from raw material sourcing to product delivery to the end consumer. This data can be integrated into the Digital Product Passport, which can then be shared with consumers and business partners.

Benefits of implementing a traceability system

| Real-time access to data | A traceability system gives you real-time access to data. This enables faster reaction to unexpected events, better production optimization, and data-driven manufacturing. |

| Improved product quality | Automated data collection allows for continuous monitoring of quality parameters. This enables quick detection and resolution of quality and safety issues. |

| Increased operational efficiency | Process automation contributes to better management of the product lifecycle and inventory. This approach boosts production efficiency and reduces operational costs. |

| Transparency and consumer trust | Providing consumers with detailed information about the origin and quality of products – e.g., via a DPP – builds trust and customer loyalty. |

| Compliance with legal regulations | Traceability systems support compliance with legal requirements related to product traceability and safety. |