PULL solution - how does it work?

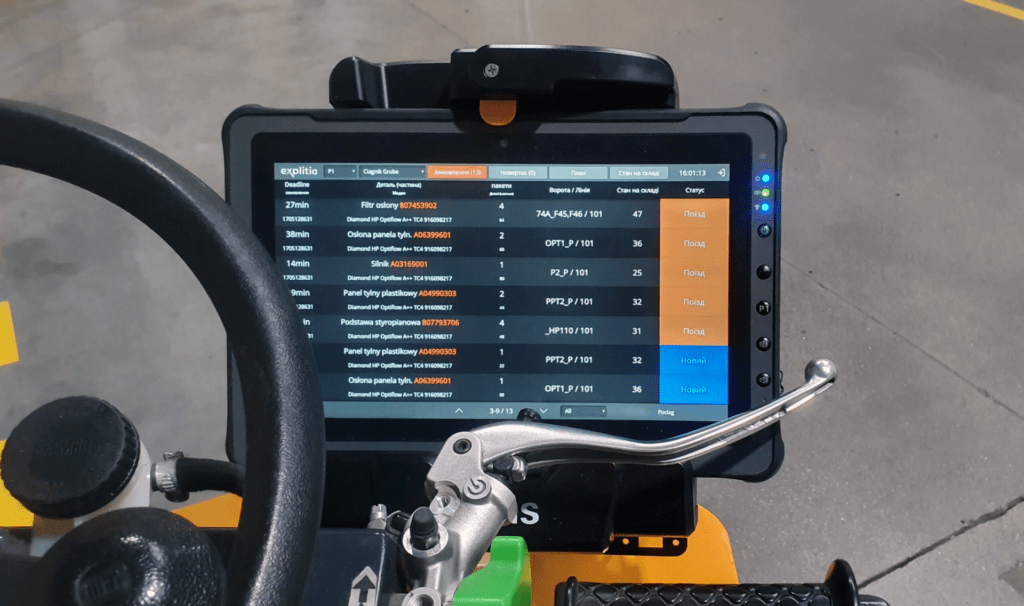

The Logistics Platform module calculates the demand for parts in such a way that the material is delivered on time. It is done on the basis of: production counters, current stock of components on the lines and the production plan. The expected material demand is presented on tablets, placed on trolleys working in warehouses and delivering components to production lines.

Why is it worth it?

| Support for the trolley operator in selecting the most urgent needs and determining the optimal route. |

| Reducing the costs associated with the delivery of materials between the warehouse and production. |

| Reduction of excess stock at production stations. |

| Ensuring order on the production line. |

| Saving time and increasing productivity - among others by better time management of employees, elimination of queues. |

| Possibility of integration with external ERP systems (including SAP), WMS, MES. |

| Scalability - the solution can be implemented as a single module, combined with other elements of the Logistics Platform, e.g. a solution for managing production buffers, as well as integrated with external systems. |

| Security - Management of user permissions. |

Contact us

Do you want to move your production plant to level 4.0? Are you interested in modern solutions for industry in the field of automation and digitisation? Be sure to let us know!