ERP and MES – Division of responsibilities

When integrating ERP and MES systems, the issue of data duplication should be addressed. As a first step, it is good to know the purpose that ERP should serve in the context of production. You also need to answer the question – at what level of detail should the values be in the company’s resource planning system, and what data should remain on lower layers.

It is important that the ERP contains all the necessary information and at the same time does not duplicate data.

A more complete vision of the production process

In the management of a production plant, it is extremely important to provide the acquired data with the appropriate context. The ERP system is responsible for giving information a business context. Additionally, the enterprise resource planning solution determines basic information about the production structure. It gives some general idea. The MES system (e.g. Production Portal) provides detailed information about the production being carried out.

Real-time data

Thanks to integration, you can effectively connect batches of raw materials used in production with serial numbers of specific products. This is extremely important in the context of quality verification and solving possible challenges related to product recalls.

Batch and serial number tracking

Thanks to integration, you can effectively connect batches of raw materials used in production with serial numbers of specific products. This is extremely important in the context of quality verification and solving possible challenges related to product recalls.

Process automation

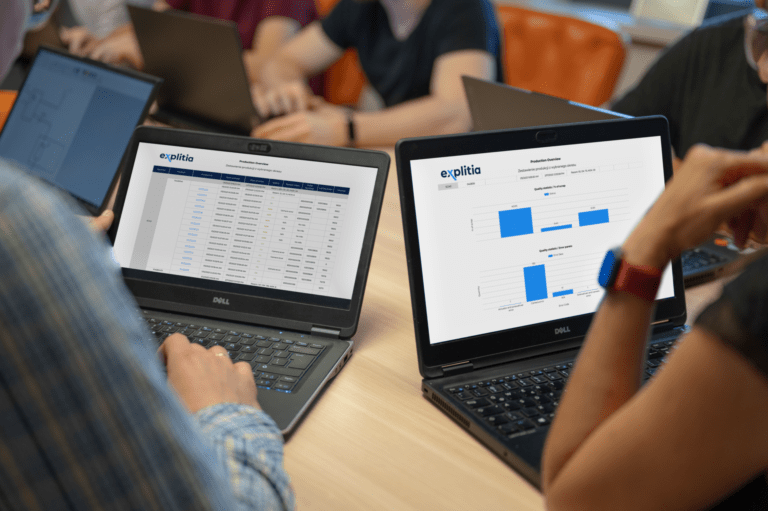

The explitia team specializes in extracting data from machines and automating processes, including communication with the ERP system. Automation of production processes allows for the elimination of paper information flow. Production orders are available for launch immediately after being released by the planner, and the work progress is visible immediately, without having to leave your desk. Moreover, the lack of manual data entry minimizes the risk of errors. The company gains a guarantee of data correctness.

Contact us

Do you want to move your production plant to level 4.0? Are you interested in modern solutions for industry in the field of automation and digitisation? Be sure to let us know!