Production management — MES and ERP data exchange

The scope of some processes can be implemented in the MES or ERP system, with the necessary synchronisation of these solutions, e.g. production planning. Ideally, both solutions are implemented in the enterprise at the same time, but this is an extremely rare case. Therefore, the scope of responsibility depends in some cases on the processes already running in the company.

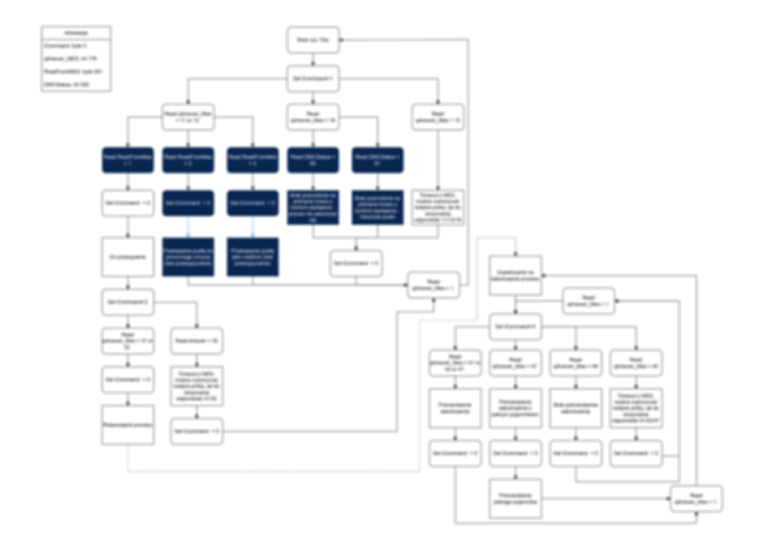

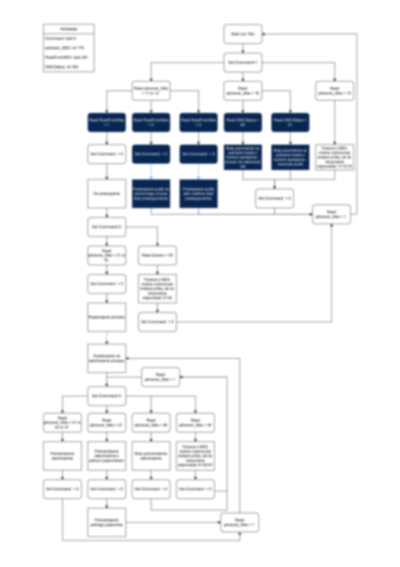

Automatic accounting - example

With the Automatic accounting module, you can, for example, plan production in detail in ERP, send the plan to the production management system and observe the degree of its implementation. You can also create a queue of orders in ERP, assign BOM, while detailed planning and distribution of orders are assigned to IT systems supporting production management.

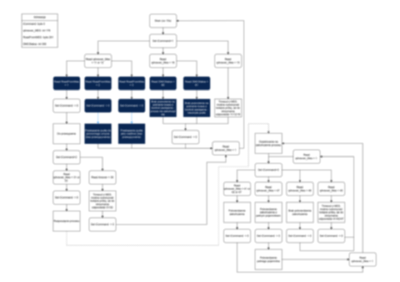

Production and enterprise management - the scope of data exchange

MES class solutions should primarily be responsible for collecting and communicating with machines and automating data circulation. In this case, the enterprise management system treats MES as a source of data automatically coming from machines and with the appropriate context. In addition, two-way communication allows you to initiate business processes in the ERP system, and then receive data directly from the machines at the appropriate level of detail.

Automatic data accounting in MES and ERP most often includes:

- downloading data on new orders to MES,

- exchanging information on:

- orders in progress,

- estimated completion date,

- orders in progress,

- transferring:

- information about completed orders,,

- detailed reports on the status and quality of production, including e.g. reasons for downtime, shortages arising during the production process, efficiency of the factory and individual machines.

Why is it worth it?

| Efficient access to data supporting production management and business decision-making (fusion of production and business data). |

| Process optimisation - no duplication and no need to rewrite the same data. The information is transferred automatically, e.g. the production counter is downloaded from the machine by the MES system and automatically sent to the ERP. |

| Much better insight into the real condition of the enterprise. |

| A way to find bottlenecks and possible optimisations. |

| Scalability of the solution - the module can be implemented as a standalone system or in connection with other tools of the Production Portal. |

| Increased production agility - business data allows you to react faster to changing conditions, guidelines, etc. |

| Greater security. |

Contact us

Do you want to move your production plant to level 4.0? Are you interested in modern solutions for industry in the field of automation and digitisation? Be sure to let us know!