A production buffer management system is a piece of a huge puzzle in the world of warehouse process management. In manufacturing facilities where every second of downtime can lead to significant losses, improving material flow and increasing control over them seems to be the ideal solution. How does such a system differ from a standard WMS? What does it offer, and what benefits does it bring? We invite you to explore this topic.

WMS system. What does it lack?

Warehouse Management Systems (WMS) manage warehouses, production halls, and logistics centers. These are extensive, sophisticated applications that ensure efficient warehouse management. However, their functionality often ends at the warehouse gates, leaving the production buffer without proper supervision. Here, a production buffer management system comes into play, extending the basic capabilities of the WMS.

Production buffer management system – the importance of the buffer

The production buffer is a vital element in the production process, serving as a temporary storage area for materials necessary for further production. Its main task is to ensure smooth access to components, which is crucial to avoid downtime and bottlenecks. WMS systems, despite their extensive range of functions, are often unable to manage this critical aspect, leading to challenges in material control outside the main warehouse. This happens because once a component leaves the warehouse – it completely disappears from the WMS system

Production buffer management system. Is it necessary?

Example of explitia customer:

In a production plant without an implemented production buffer management system, workers use sticky notes placed on a single board. They write down what, where and in what quantity is in stock. Additionally, a person is employed to supervise the production stations and ensure their constant supply. When components begin to run low, such an employee approaches the board, looks for the specific item and reports the fact to the next person responsible for delivering products from the warehouse to the buffer.

This procedure is extremely time-consuming and can generate many mistakes and problems, such as a break in production continuity due to a lack of materials delivered in time. Despite its low efficiency and high likelihood of errors, such a solution is used in some plants.

Main benefits

The production buffer management system provides information about the number and exact location of items in the buffer. This introduces a series of benefits that significantly affect the efficiency and smoothness of production processes:

- Easier delivery of materials to the production line: Thanks to precise monitoring of buffer statuses, the system minimizes the risk of production downtimes due to a lack of components.

- Reduction of human errors: Limiting the risk of mistakes through the automation of material access and systematization of supply processes.

- Optimal use of warehouse space: Buffer management algorithms allow for efficient use of available space, following principles such as FIFO (First In, First Out), LIFO (Last In, First Out), or priorities specific to certain types of materials.

These systems offer a high degree of configuration, allowing for the customization of buffer management priorities and rules, according to the unique needs of a production facility. They enable management of material retrieval sequences, preferences regarding their locations, and facilitate decision-making processes related to inventory management.

Production buffer management system – launching the application

The application for managing production buffers is launched on a server at the production site. The displayed interface can be accessed in two ways:

- URL address in an internet browser – allows for operation on any device at any time.

- Dedicated application on a tablet – in this case, nothing else is installed on the device, and the application functions as if it were the only thing available on the tablet. Additionally, it can be mounted on a forklift, further enhancing work efficiency.

Visualization capabilities on the tablet

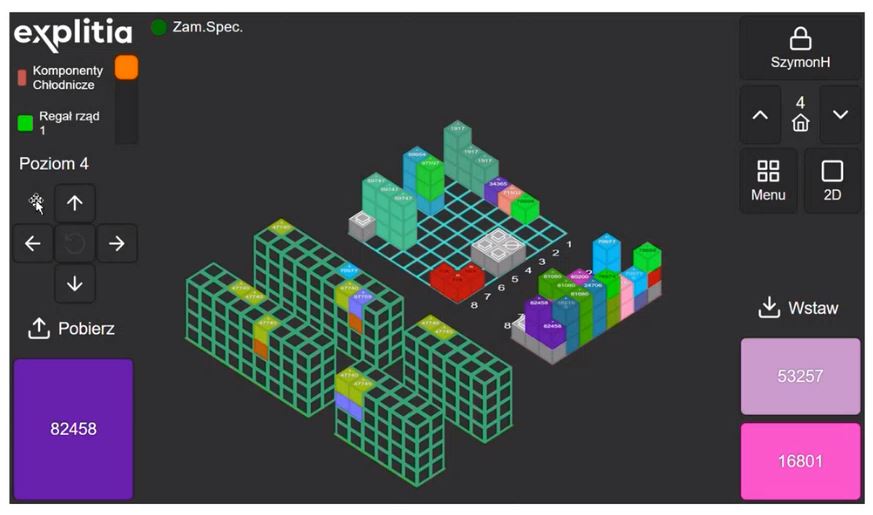

Three-dimensional view – a multi-level buffer, where rectangular modules are visible. Users have the freedom to manipulate the perspective to ensure visibility of each side and to make sure that individual elements do not overlap. When an operator needs a specific component, the relevant module is highlighted, indicating its location.

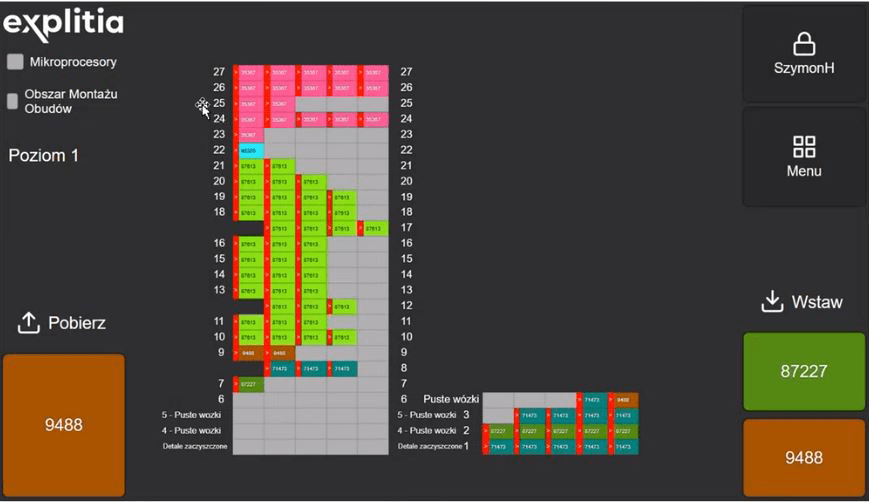

Flow channel view (two-dimensional) – used when components are placed on mobile platforms arranged in rows without division by height. This mechanism maintains the FIFO principle. Picking a platform moves the others toward the exit. This makes it possible to take out the cart that has been in stock the longest (visible in the following graphic as the platform on the left). A newly added platform from the right side automatically moves to the left to occupy the nearest free position at the exit.

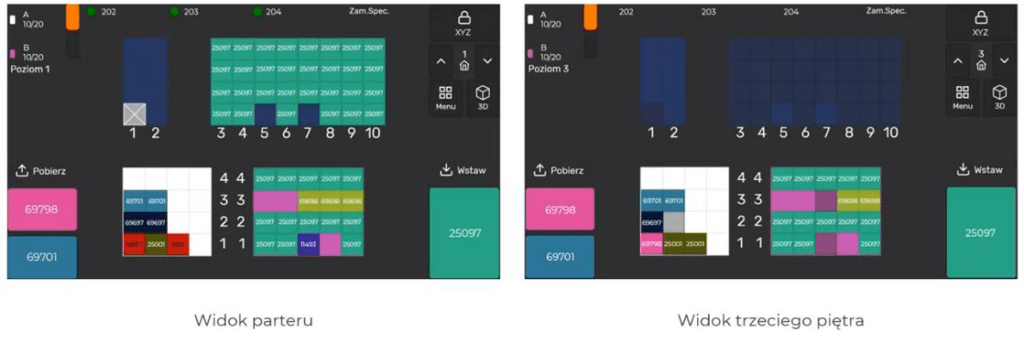

Two-dimensional multi-level view – displays one buffer with many separate places where products can be stored.

Administrator view – available from an office computer. It functions through an web browser, offering a simplified presentation of data that facilitates viewing larger areas. Instead of focusing on detailed locations, it focuses on the overall use of warehouse space.

An added benefit for managers is access to reports. It provides information on, among other things, time, product storage or quantities of items inserted and retrieved on specific days.

Production buffer management systems are a tool for modern manufacturing facilities, enabling not only more efficient material management but also significantly impacting the fluidity and efficiency of production processes. Their implementation is a step towards an automated, well-managed buffer environment capable of meeting the demands of the contemporary market.

Are you interested in solutions related to in-plant logistics? Do you want to ensure optimal placement of goods in the warehouse? Are you looking for flexible solutions supporting buffer management? Contact us.

Contact us

Do you want to move your production plant to level 4.0? Are you interested in modern solutions for industry in the field of automation and digitisation? Be sure to let us know!