Digitalization of the furniture industry – process optimization with explitia

explitia offers the Production Portal, a comprehensive tool supporting digital transformation in furniture manufacturing plants. Its modules, including the Energy Management System (EMS), are tailored to the specific needs of the industry, enabling process optimization and increased efficiency.

Key challenges in the furniture industry – explitia’s solutions

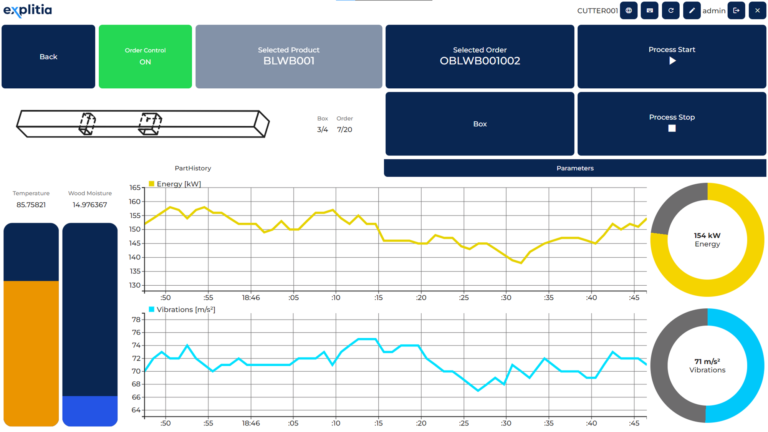

2. High energy costs and difficulties in controlling them

Solution: EMS – Energy Management System

- Monitoring energy consumption at the machine and production line levels.

- Identifying areas with the highest energy losses.

- Generating reports and analyses for cost optimization.

- Automatic alerts for exceeding predefined energy consumption limits.

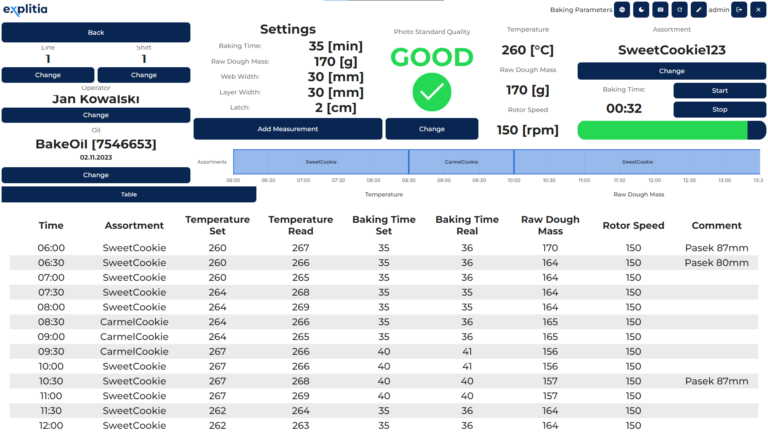

4. Lack of full product traceability

Solution: Traceability

- Comprehensive tracking of production processes – from raw materials to finished products.

- Quick location of defective batches in case of complaints.

- Compliance with traceability and ESG regulations.

Why implement the Production Portal in furniture manufacturing?

explitia delivers solutions perfectly tailored to the needs of the furniture industry, providing real benefits from the very first days of implementation.

Some key advantages include:

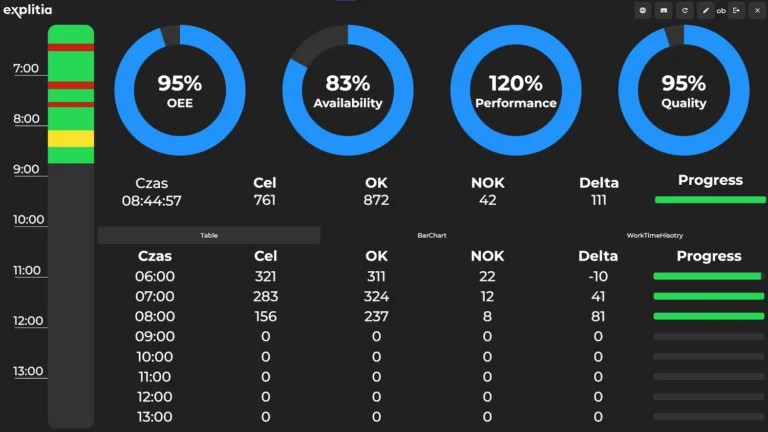

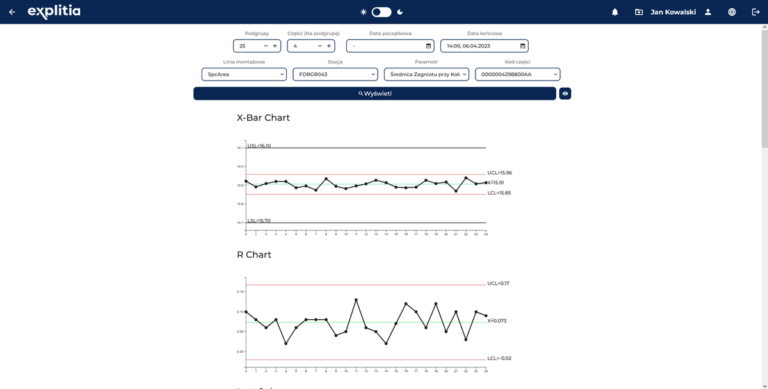

Cost Optimization – Thanks to the EMS module (energy consumption tracking) and efficiency monitoring, operational costs can be significantly reduced.

Process Transparency – Full insight into production status, energy consumption, and quality parameters.

Automation – Reduction of errors caused by manual work and real-time data integration.

Regulatory Compliance – The traceability system ensures adherence to quality and ESG standards.

Flexibility – Step-by-step module implementation tailored to furniture production specifics.

Scalability – Solutions adaptable for both small workshops and large production plants.

Fast Results – System modules deliver measurable benefits within a short time after implementation.

Why choose explitia?

Our solutions are built on years of experience in the manufacturing sector, allowing us to develop systems that meet the needs of furniture producers – from large industrial plants to smaller factories. Our systems enhance daily operations, reduce costs, and increase process transparency.