The Production Portal is a modern digital tool that supports the digital transformation of manufacturing enterprises, optimizing key processes and minimizing costs.

Our IT solution is tailored to the specifics of the dairy industry, which is characterized by high production dynamics and the use of various packaging machines.

All system modules are built using web technology, meaning you can access them from any device with an internet connection. Whether you are using a computer in the office, a tablet on the production floor, or a phone during a client meeting, the system is always within reach.

It can be deployed both on local infrastructure and in the cloud, ensuring that production data is always available when you need it. The system requires appropriate authentication and is fully compliant with cybersecurity standards.

Key challenges in the dairy industry – IT solutions from explitia

1. Efficiency in packaging processes

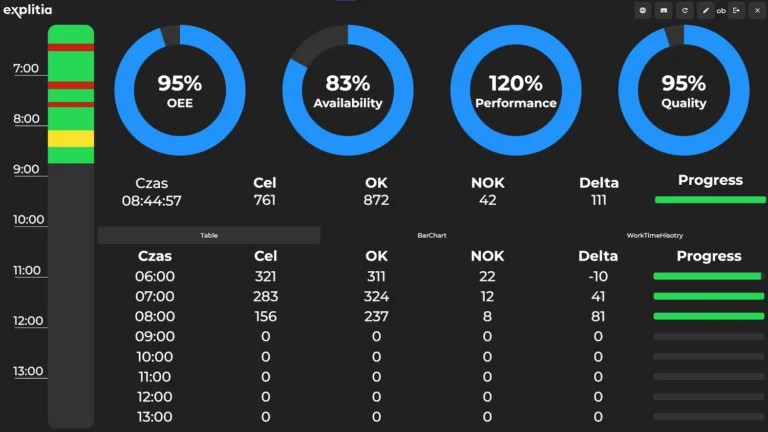

Many manufacturers struggle with real-time data availability. With the efficiency module in the Production Portal:

• we measure real-time production counters of packaging machines;

• we analyze efficiency indicators (OEE): availability, performance, and quality;

• we identify and monitor downtimes, failures, and their causes;

• we provide insights into Pareto charts and key production summaries hour by hour.

2. Traceability – product identification

The traceability module allows tracking of every product at each stage of its production (from raw material to final product). This provides:

• access to the full history of individual production batches (milk origin, components, pasteurization conditions);

• the ability to scan product cups to retrieve detailed information about the production process;

• identification of the operator, components, process parameters, and specific tanks involved in production.

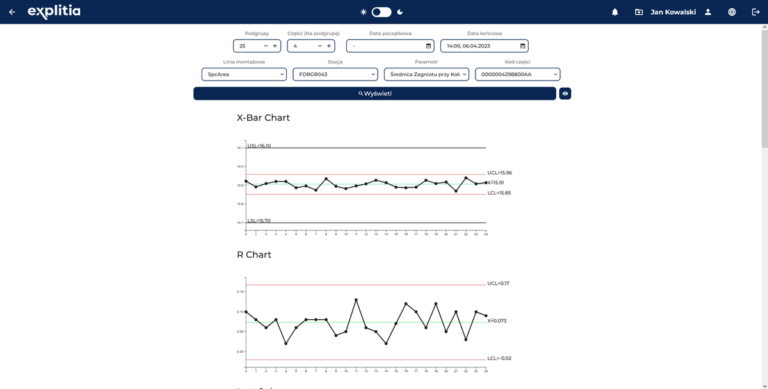

3. Maintaining high quality with SPC (Statistical Process Control)

Automated statistical process control helps predict deviations from norms. Check out the benefits of this explitia solution:

• the system monitors production parameters and sends alerts if processes start to deviate from set standards;

• product rejection losses are minimized;

• notifications can be sent via email or SMS.

4. Flexibility in production planning and execution

The production planning module in the Production Portal enables:

• dynamic assignment of production orders to packaging machines, considering the need for retooling, cleaning, and sterilization;

• optimization of schedules based on real-time production data;

• ongoing monitoring of plan execution, with the ability to respond quickly to changes (e.g., sales department priorities);

• receiving feedback from packaging machines after implementing the appropriate software module that enables data collection.

Why implement the Production Portal?

Ready to handle dynamic processes – the system is perfect for environments with frequent product changes and machines that require frequent retooling.

Scalability – it can be implemented on packaging machines and extended to other production processes. The deployment can start with a single production machine and module, then be expanded step by step.

Quick results – modules are designed for rapid deployment, providing measurable benefits within the first few weeks.

Custom fit – the system can be tailored to the specific processes and requirements of your company.

Production Portal in the food industry

Implementation examples and our experience

We developed our Production Portal based on our observations and experience in yogurt and soft cheese factories. Thanks to implementations in the food industry, we have gained a deep understanding of the complexities of dairy production.

This is the carefully considered result of our long-term strategy. We thoroughly analyze the unique needs of dairy producers and create IT solutions tailored precisely to their requirements.

Additionally, before we begin technological implementation, we conduct a comprehensive analysis of every stage of the production process. This approach ensures that the provided solutions are fully integrated with real business processes.

We do not offer ready-made technological templates – we design custom systems that precisely address the needs of your manufacturing facility.