The bakery and confectionery industry has a unique character. This is influenced by factors such as the high turnover of ingredients, the need for innovation in response to changing consumer trends, and the necessity to scale production. Therefore, this sector requires flexible and technologically advanced solutions. Aware of these challenges, we have developed the Production Portal.

Production Portal – the path to digitalization in the baking and confectionery industry

To address these challenges, we created the Production Portal, an advanced digital tool that supports the digital transformation of the baking industry. The system minimizes costs and reduces downtime while optimizing key processes such as:

- production management,

- quality monitoring,

- tracking batches of raw materials and finished products.

The solution is adapted to the nature of the industry, where both process automation and the ability to quickly reconfigure production lines for different product types are crucial.

All system modules are built using web technology, meaning you can access them from any device with an internet connection. Whether you use a computer in the office, a tablet on the production floor, or a phone during a client meeting, the system is always within reach.

It can be deployed on local infrastructure or in the cloud, ensuring that production information is always and everywhere available – exactly when you need it.

The system requires appropriate authentication and is fully compliant with cybersecurity standards.

The Production Portal is your path to Industry 4.0.

Challenges in the baking industry – IT solutions from explitia

1. Efficiency in milling and packaging processes

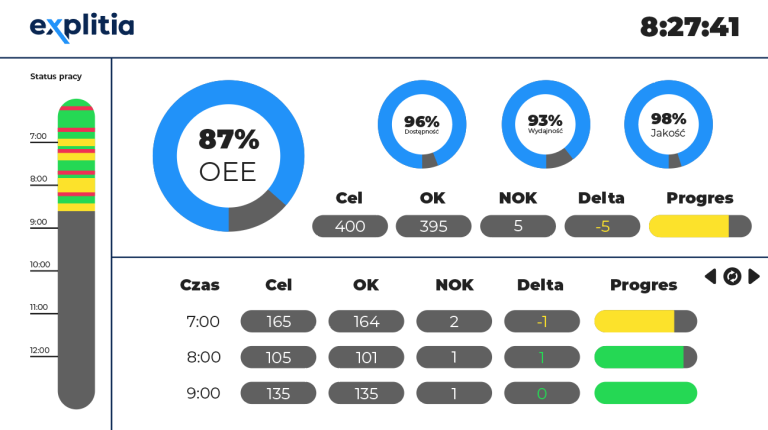

Solution: Efficiency and OEE module

- Real-time measurement of quantities for each flour and bran stream in the mill, as well as bakery and confectionery mixes, including production counters for packaging and ventilation machines.

- Analysis of OEE indicators (availability, performance, quality).

- Monitoring and identification of downtimes, failures, and their causes.

- Continuous insight into Pareto charts and key production summary values hour by hour.

2. Traceability – full product identification

Solution: Traceability module

- Tracking every stage of product manufacturing from raw material to the final product.

- Full history of raw material deliveries (supplier data, quantity, grain type, batch number, quality parameters, silo identification).

- Identification of production processes during raw material cleaning and preparation, including grain milling (mill identification, process parameters such as milling efficiency, values of individual flour streams, and quality factors such as ash content and moisture).

- Flour blending: when combining different batches, the system records information about input batches (origin of the raw materials used for the flour) and blending ratios.

- Identification of the packaging line and assignment of batch numbers for flour bags/packs.

3. Real-time quality management

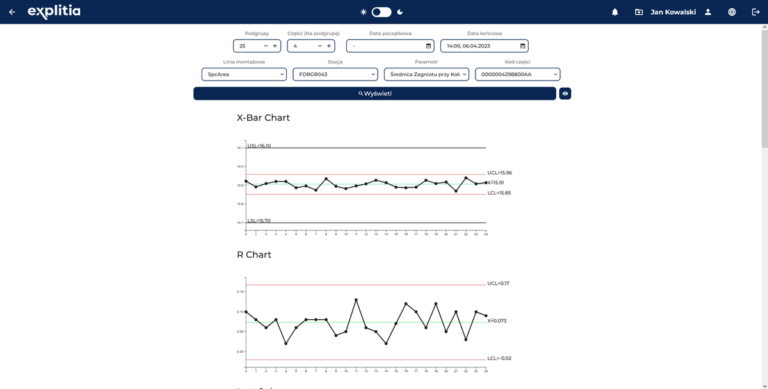

Solution: SPC (Statistical Process Control) module

- The statistical process control system monitors the degree of grain cleaning on each machine.

- Production parameters such as moisture content, protein levels, and ash content are continuously tracked, with alerts sent if the process deviates from established standards.

- The system monitors air pressure before and after the cyclone filter, airflow measurement, and dust concentration in exhaust air.

- Immediate notifications are sent via email or SMS.

4. Flexibility in production planning and execution

Solution: Production planning module

- Efficient assignment of production orders to milling lines and packaging machines, taking into account changeovers, product assortment changes, and optimal production continuity.

- Increased scheduling efficiency using real-time data from milling lines, including flour quality and silo availability.

- Continuous monitoring of production plan execution, allowing for quick adaptation to changes such as shifting priorities based on current orders or the need to respond to variable production conditions (e.g., raw material quality fluctuations or machine failures).

Why implement the Production Portal?

Ready for dynamic processes – the system is ideal for environments with frequent product variations and frequent machine changeovers.

Scalability – deployable on packaging machines and across additional production processes. Implementation can start with a single production machine and one module, then expand progressively.

Quick results – modules are designed for rapid deployment, delivering measurable benefits within the first few weeks.

Tailored fit – the system can be adapted to the specific processes and requirements of your company.

Implementation examples and our experience

The Production Portal has been successfully implemented in the food industry, including in bakeries and confectionery production facilities. Our experience allows us to understand the unique needs of producers of bakery products, mixes, spices, concentrates, and ready-made products such as bread and snacks, enabling us to develop the best IT solutions for digital transformation in the baking industry.