Rising utility costs are keeping many manufacturers awake at night. Efficient energy consumption management is becoming one of the top challenges in industrial operations. Is there an effective way to optimize production processes and reduce expenses? The answer is yes. Discover how explitia EMS – an intelligent energy management system – can help.

The four most cost-intensive utilities in manufacturing

More and more production plants experience how burdensome utility costs can be. The issue is particularly significant in the food, chemical, steel, cement, and paper industries, where processes are extremely energy-intensive. Let’s look at the four utilities that generate the highest costs:

1. Electricity

Electricity powers machinery, lighting, transport lines, and cooling and ventilation systems. While modernizing equipment, switching to energy-efficient motors or LED lighting brings savings, real cost control starts with comprehensive utility metering.

2. Gas

Natural gas is widely used for heating, pasteurization, drying, and as a feedstock in the chemical industry. Due to fluctuating prices, optimizing gas usage directly impacts operational costs.

3. Water

Water plays a key role in processes like cooling, washing, dissolving, and steam generation. It’s also a raw material in food, beverage, pharmaceutical, and chemical production. Whether from municipal supply or deep wells, quality monitoring and precise measurement are essential.

4. Compressed Air

Used in automation, packaging, and pneumatic transport, compressed air is one of the most expensive utilities. Even small leaks can cause significant losses without proper monitoring.

Each of the above-mentioned utilities plays a crucial role in production processes, and their optimal use can lead to significant savings.

However, this comes with certain challenges for manufacturing plants. What are they? Namely:

- outdated technology,

- lack of consumption monitoring,

- leaks and inefficiencies,

- poor process management,

- inefficient maintenance,

- insufficient automation and system integration,

- lack of energy recovery,

- poor media storage,

- low employee awareness.

explitia EMS – an investment, not a cost

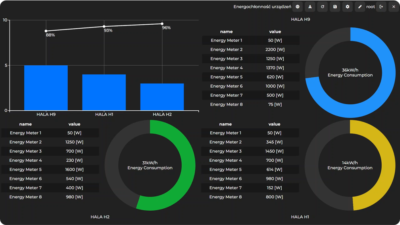

explitia EMS (Energy Management System) enables real-time utility monitoring and supports your plant’s digital transformation.

It’s more than just meters. It’s a smart platform that allows:

- real-time utility consumption monitoring – integration with energy, water, and gas meters enables continuous data collection;

- analysis of inefficiencies and downtimes – identification of high energy consumption areas and detection of excessive usage (e.g., during downtimes or idle runs);

- cost allocation – automatic conversion of energy consumption into costs, taking into account tariff structures, facilitates accurate allocation of production expenses;

- process and production planning optimization – ongoing monitoring and analysis of energy parameters with recommendations for cost reduction support energy management in manufacturing;

- automated reporting – generation of ESG reports simplifies carbon footprint tracking and compliance with sustainability requirements;

- loss and anomaly detection – the ability to identify excessive energy consumption, e.g., during downtimes or idle machine states.

Implementing EMS can save hundreds of thousands of PLN annually, with investment ranging from PLN 150,000 to 200,000, and an ROI of 6–12 months.

Integration EMS system with other systems

EMS is just the first step. It can be integrated with:

- MES (Manufacturing Execution Systems),

- APS (Advanced Planning and Scheduling),

- ERP (Enterprise Resource Planning).

Digitalization despite an old machine park

Many business owners worry that older equipment is an obstacle to production digitalization. Are these concerns justified? Absolutely not. There is no need to immediately invest in a new machinery fleet. These systems also work effectively in older facilities, providing data that forms the foundation for further production cost optimization. Thanks to them, it is possible to manage production more efficiently, prevent failures through early detection of utility consumption anomalies such as sudden drops in compressed air pressure or increases in motor temperature, and plan the next steps of the transformation journey.

Digitalization is not the future. It’s the present. explitia EMS is your first, critical step into the Industry 4.0 era.