In today’s dynamically developing industrial world, where modern technologies are changing the traditional approach to manufacturing, there are more and more tools optimizing production processes. One of the key indicators, in the context of Industry 4.0, is OEE (Overall Equipment Effectiveness). It allows for a detailed analysis of machines and devices in terms of three main elements. Do you know the benefits of OEE? Do you have everything you need to implement it? You will find a complete set of information in the article below!

What is OEE?

OEE is an indicator of machine utilization that enables the assessment of whether a given device produced with the expected quality and efficiency. It is a composite parameter, based on three fundamental indicators: availability, performance, and quality. Each of these elements is evaluated based on dedicated formulas, which can be adapted to the specific needs of a given production facility.

- Availability refers to the time when the machine is ready to work compared to the planned production time. It includes planned downtimes, e.g., breaks or machine setups, and unplanned downtimes such as failures. It is an indicator that often undergoes adjustments depending on the individual needs of the machine park.

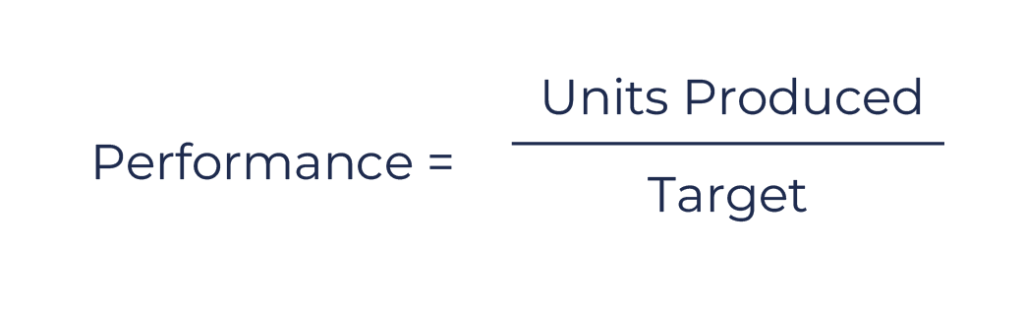

- Performance measures how quickly a machine produces goods in relation to its theoretical maximum efficiency. It includes various factors, including short-term downtimes and process slowdowns. It denotes the number of units produced, relative to the set goal.

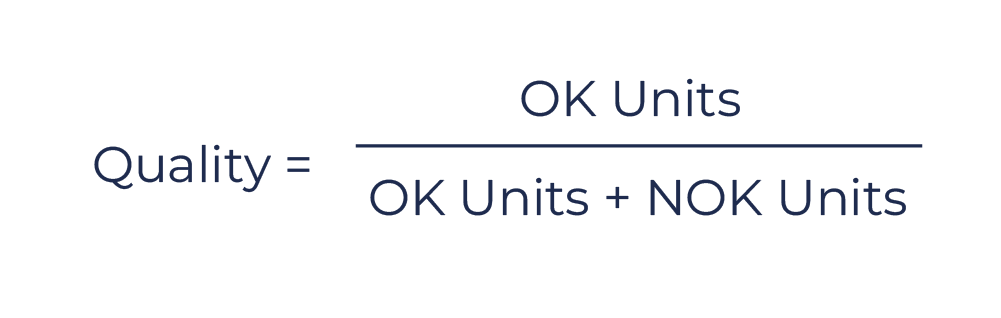

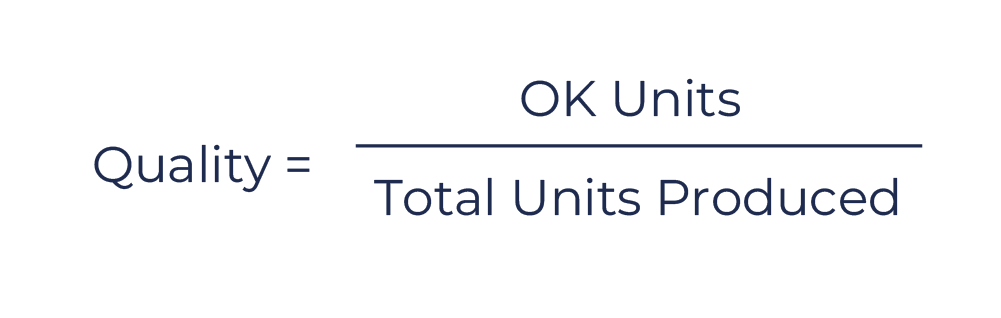

- Quality focuses on the proportion of products that meet quality requirements to the overall number of produced units. It is usually the ratio of defect-free products (OK units) to the total number of produced units (OK + Not OK units).

The OEE metrics itself is simply a multiplication of the above parameters, and is always calculated in the same way:

Benefits of Implementing OEE

The main benefit of implementing OEE is the ability to observe the real efficiency of machines and adequately manage the machine park. Thanks to the installed web application, it is possible to observe and analyze the state of the plant in terms of OEE metrics and the condition of the machine from the office. This allows us to see the level of OEE achieved by individual devices. Depending on this, we can determine whether the existing machine base is sufficient to achieve the planned production, or whether it is necessary to purchase new devices. Moreover, monitoring OEE allows for the identification and elimination of downtimes and failures, which directly translates into cost reduction and increased production efficiency.

Requirements for Implementing OEE

The implementation of this indicator is the first step in introducing the concept of Industry 4.0. It is a relatively easy element of digitizing the production facility, which allows for the gradual introduction of further changes. However, to achieve this, several elements are necessary.

- A PLC (Programmable Logic Controller), which collects data from the machine about the number of units produced with OK status (good units produced), with NOK status (defective units), and the status of the machine, i.e., whether it is working automatically, has a break, or maybe a failure.

- Network infrastructure and a server, on which a dedicated application for the analysis and visualization of OEE data can be run. Such an application can be accessible both on large screens in the production hall and on computers, allowing easy access to data and their analysis from the office. In the absence of a server, the system can be run locally, on a computer by the machine.

OEE as a Gateway to Industry 4.0

The implementation of OEE opens the way to further innovations within Industry 4.0, such as traceability systems, which allow for even more precise management of production and product quality. Thanks to the infrastructure implemented for monitoring OEE, it is easy to extend the functionality to additional modules such as barcode scanners, which enable tracking of specific product batches.

Implementing the OEE indicator is a key step on the path to implementing the principles of Industry 4.0. By precisely monitoring of machine availability, performance, and quality, it is possible not only to optimize production processes but also to efficiently manage machine resources. The implementation of OEE allows for gaining a competitive advantage by increasing efficiency, reducing production costs, and improving the quality of manufactured goods.

Contact us

Do you want to move your production plant to level 4.0? Are you interested in modern solutions for industry in the field of automation and digitisation? Be sure to let us know!