IT systems in industry play a crucial role in managing production processes

Modern manufacturing companies base their operations on advanced technologies that enable automation and monitoring of key activities. The implementation of appropriate IT systems allows companies to optimize production processes, thereby enhancing operational efficiency.

ERP systems as the key to effective management

Among the available IT solutions, ERP (Enterprise Resource Planning) systems stand out as the most essential. For manufacturing companies, they are a vital tool that integrates various areas of activity, such as logistics, finance, and human resource management. Implementing an ERP system enables more effective control and management of operations, leading to better business results.

IT Systems in industry – MES

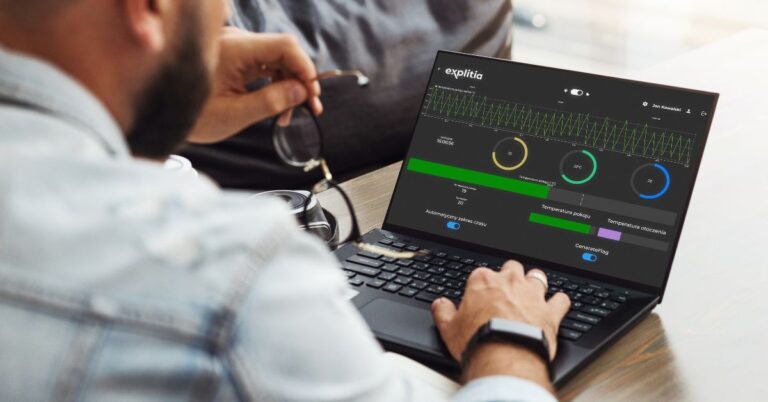

Equally important are MES (Manufacturing Execution System) solutions. This system is responsible for managing production processes. MES monitors activities on the production floor in real-time, allowing for quick responses to any deviations from the norm.

Planning IT systems implementation with future growth in mind

Planning the implementation of IT systems in manufacturing companies requires taking into account the future development of the organization. It is crucial that these systems are scalable, allowing the company to adapt to increases in employees, machines, or changes in production processes. The right flexibility in an ERP system enables the company to grow without the need for frequent software replacements.

However, excessive customization of solutions should be avoided, as over-complicating the system can lead to difficulties in maintaining it and costly updates. Instead, quick implementation of standard solutions can yield faster returns on investment.

Tailored or modular solutions?

The decision between custom-made solutions and ready-made modules should be carefully considered. Every manufacturing enterprise has unique requirements related to technology, machinery, or product specifications. For this reason, the implementation of a MES system may require some customization to meet the specific needs of the production process.

However, ready-made modules have their advantages – they are based on the experiences of other companies, which reduces the risk of errors and shortens the implementation time, bypassing the phase of software development and testing. The key is to find a balance between customization and the use of proven, standard solutions.

Contact us

Do you want to move your production plant to level 4.0? Are you interested in modern solutions for industry in the field of automation and digitisation? Be sure to let us know!

IT systems in industry – Benefits of open source solutions

Open source solutions in IT systems for industry can significantly speed up implementation and reduce costs. Open-source software offers ready-made modules that can be tailored to a company’s individual needs, which is especially beneficial for ERP-class solutions. Thanks to open source code, companies can flexibly modify the software to fit specific requirements.

However, in the case of MES systems, the situation is more complex because production processes are unique to each company. This makes it more difficult to find a ready-made open-source solution that fully meets the needs of every manufacturing facility.

New technologies supporting system integration

Modern technologies, such as data synchronization and OPC (Open Platform Communications), facilitate data standardization between different systems within the company. The integration of IT systems like ERP, MES, and other business tools, such as quality control systems or maintenance management, allows for optimal management of data flow.

Data standardization enables companies to perform more effective diagnostics and simplifies the implementation of new technological solutions, such as artificial intelligence and predictive systems. As a result, companies can better manage their resources and introduce innovations based on solid data foundations.

The importance of data standardization

Standardization is crucial in managing IT solutions in the industry. It prevents excessive customization, lowering system maintenance costs and speeding up the diagnostic process. Thanks to standardization, it is possible to manage data from different sources more efficiently, which improves production quality and increases operational efficiency.

Standardized IT systems also support the implementation of advanced technologies, such as artificial intelligence. This can significantly enhance the forecasting and optimization of production processes.

Managing IT systems in the manufacturing industry is one of the key elements ensuring the efficiency and growth of companies. ERP and MES solutions are essential tools for optimizing processes and monitoring production in real-time. Companies should strive for the standardization of their IT systems to fully exploit their potential and simplify data management as well as production process management. In this way, they can gain a competitive edge while facilitating the introduction of innovative technologies such as artificial intelligence or automation. This is the essence of Industry 4.0.