Modern Technologies have firmly embedded themselves not only in workplaces but also in our everyday lives. Today, solutions that were mere dreams a few years ago are now used practically everywhere in the world. These technologies simplify many tasks we encounter daily—whether in our personal or professional lives.

The Internet of Things (IoT) and its industrial counterpart, the Industrial Internet of Things (IIoT), have revolutionized the management of devices in homes and factories. You may wonder—how do these technologies work? In this article, we will answer this question and explore their applications, as well as the practical benefits they bring.

1. How Does the Internet of Things Work, and What Are Its Applications?

The Internet of Things (IoT) is a technology that enables various devices to connect to the internet, allowing them to be controlled remotely. Examples of such devices include thermostats, smart bulbs, and even large home appliances like washing machines and refrigerators. The applications of the Internet of Things are, therefore, quite broad.

With remote control capabilities, IoT systems make device management intuitive and convenient. Through specialized apps, you can set up many things even when you’re away from home. You no longer need to worry about forgetting to turn off the lights or start the washing machine — you can do it all remotely! IoT technologies not only simplify everyday life but also help save energy, reducing various costs. A network of smart devices, in turn, easily transforms our homes into smart homes.

An interesting example of IoT applications is smart plugs. These can be programmed to turn on and off at specific times and monitor electricity usage, allowing for better control over expenses. This also enhances household management efficiency.

IoT Solutions – Ensuring Safe Usage

When discussing the Internet of Things (IoT), we must not overlook security issues. It is true that any internet-connected device can become a target for cyberattacks. However, we can effectively protect ourselves and our devices. A key aspect is securing your Wi-Fi network. Beyond setting a strong password, consider creating a separate network dedicated exclusively to IoT devices.

This separation reduces the risk of unauthorized access to your sensitive data. Additionally, to protect your privacy, you might also consider providing a separate network for guests, isolated from your primary resources. This not only protects your devices but also enhances overall security.

2. Understanding IIoT – Smart Technologies for Industry 4.0

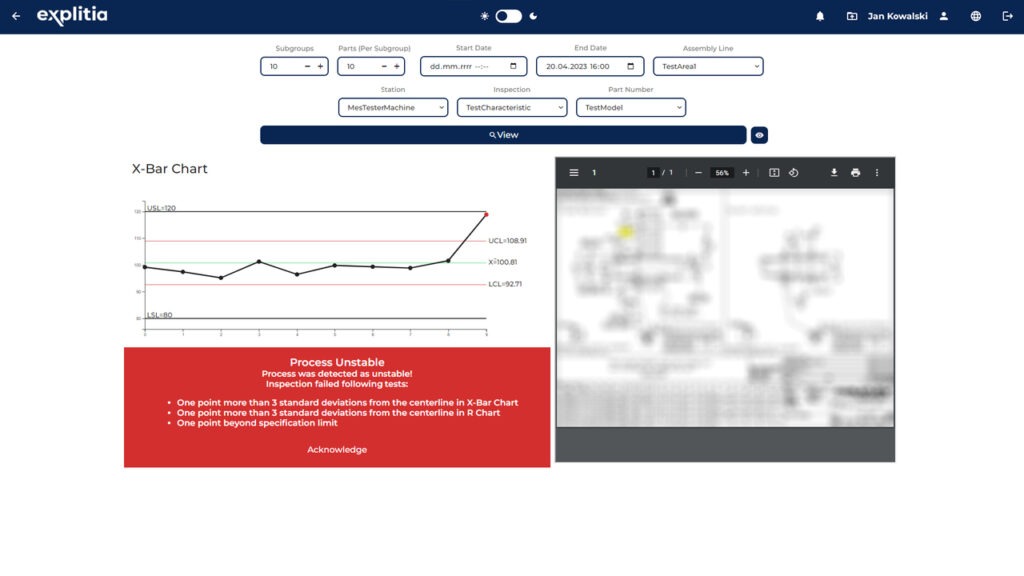

The Industrial Internet of Things (IIoT) builds upon the concept of IoT, tailored specifically for industrial needs. It consists of a network of connected devices, machines, and sensors, allowing real-time monitoring and analysis of production processes. IIoT enables ongoing control of machine parameters, allowing for immediate responses to changes or failures.

Imagine a production facility with sensors tracking indicators such as humidity, energy consumption, and temperature. Industrial IoT systems collect real-time data, enabling rapid process optimization and increased production efficiency. As a result, decision-making becomes easier, and losses are minimized.

IoT Sensors: Real-Time Machine Monitoring with the Industrial Internet of Things

Monitoring the condition of equipment and its basic parameters is only a part of IIoT’s capabilities. We also benefit from advanced diagnostic information, enabling the early detection of potential faults and allowing for maintenance planning before a breakdown occurs.

IoT sensors allow for real-time data analysis, giving employees a comprehensive understanding of the production line’s operations. They can then make more informed decisions, leading to optimized processes and increased operational efficiency.

Production Processes – How Do Wired Connections Enhance IIoT Reliability?

Compared to wireless networks, wired networks are known for their greater reliability. Therefore, in industrial settings, wired connections are preferred, especially for IIoT devices. In critical production processes, the continuity of data transmission and operation is essential. Even a brief interruption in transmission can lead to serious issues, making the stability of wired connections a priority.

With cables, a production facility can be assured that data from machines is transmitted without disruptions. This ensures that monitoring systems function smoothly and without downtime, which in turn enhances overall efficiency and minimizes the risk of failures.

Data Protection in Industrial IoT

Security in IIoT is crucial, perhaps even more so than for consumer IoT used in homes. In industrial environments, devices operate within carefully secured, closed networks, isolated from the public internet to enhance protection. Communication is conducted over encrypted connections, significantly reducing the risk of unauthorized access to sensitive data or trade secrets.

It’s important to remember that IIoT security extends beyond information protection. Safeguarding machines from potential takeovers by third parties is equally vital. In the industrial sector—where precision and security are top priorities—such threats could lead to severe consequences, including system failures or production stoppages. These disruptions could result in substantial financial and reputational losses for the company.

3. IIoT as a Key to Modernizing Outdated Machinery

One of the main advantages of the Industrial Internet of Things (IIoT) is the ability to upgrade older machines without the need for complete replacement. Many production facilities still operate equipment that’s several decades old. Instead of investing in new machinery, companies can integrate modern IIoT sensors. These allow for real-time monitoring and analysis of machine performance, optimizing operations without the need for replacement.

By installing sensors, industrial facilities can introduce advanced digital solutions without overhauling their entire infrastructure. This approach leads to significant savings while also enhancing flexibility and efficiency in managing production processes.

Industrial Internet of Things: Applications for Utility Monitoring in Industry

Another important application of IIoT in industry is the ability to monitor utility consumption, such as electricity, water, and gas. IIoT devices equipped with sensors enable real-time tracking of consumption at every stage of production. Data management provides precise cost control and more efficient resource management.

With data analysis provided by IIoT systems, production facilities can better align energy consumption with current operational needs, directly contributing to cost reduction and performance optimization. These solutions not only offer financial savings but also promote sustainable resource use. Additionally, data collection allows for easy access and utilization in the future.

4. The Internet of Things – Check if Your Devices Are Ready for the Future

Innovative IoT technologies are revolutionizing management both in homes and in industry. The Internet of Things (IoT) enables remote control of household devices, offering benefits like energy savings and increased convenience. On the other hand, IIoT applications in virtual factories support machinery and production process management, leading to improved operational efficiency and enhanced workplace safety.

Regardless of the application, security remains a key aspect for both technologies. Network protection, strong passwords, and proper data security measures are foundational elements that must be implemented to ensure reliability and defense against potential threats.

Looking to the future, it’s clear that IoT and IIoT will play pivotal roles in the continued development of technology. With the support of AI (artificial intelligence), homes will become smarter, and production facilities will be more automated. Resource management efficiency will be further optimized. Investing in these technologies today is a worthwhile step to fully reap their benefits in both private and professional life.

Implementing Internet of Things Solutions

We invite you to watch the latest episode of our videopodcast. In this episode, we delve into various aspects of production facility digitization and its potential to improve processes within companies. This is a great opportunity to explore how modern technologies can impact production efficiency and automation. We also encourage you to share your experiences with implementing IT solutions in production facilities. Together, we can discover innovative solutions that will help effectively harness the potential of modern technologies in a production setting. Take advantage of the innovations offered by adopting Industry 4.0 principles in your business today!

Contact us

Do you want to move your production plant to level 4.0? Are you interested in modern solutions for industry in the field of automation and digitisation? Be sure to let us know!