Monitoring and optimizing energy consumption is one of the most critical aspects of effective production management. Manufacturing companies face continuously rising electricity costs and tightening ESG regulations. As a result, businesses are increasingly looking for advanced solutions that enable precise monitoring and optimization of energy consumption. Implementing Energy Management Systems (EMS) allows companies to effectively reduce energy losses, optimize usage, and improve operational cost planning. If you manage a business and energy consumption optimization is a key concern for you, it’s time to get acquainted with EMS.

What is an EMS System?

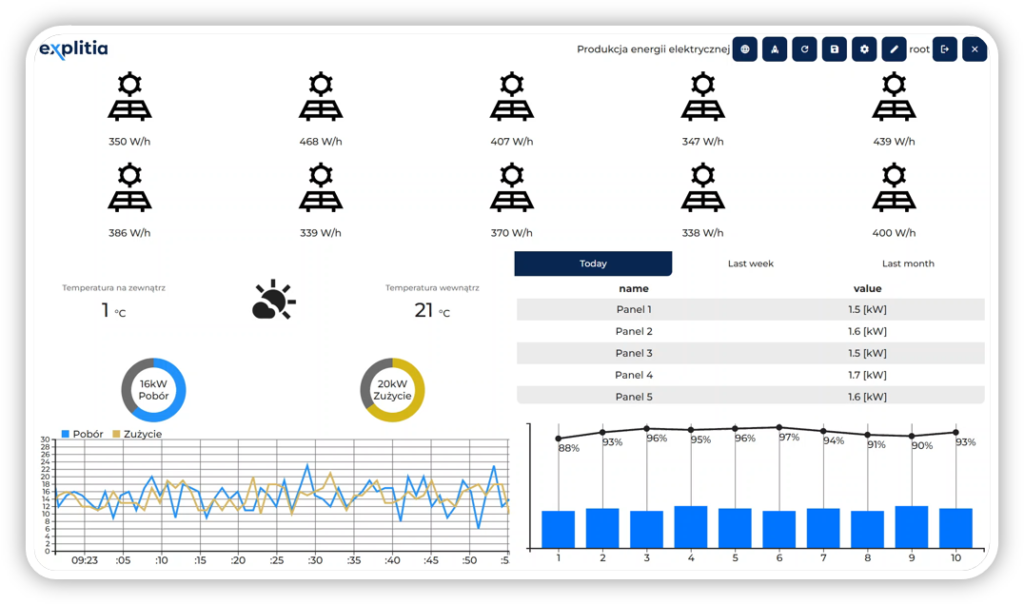

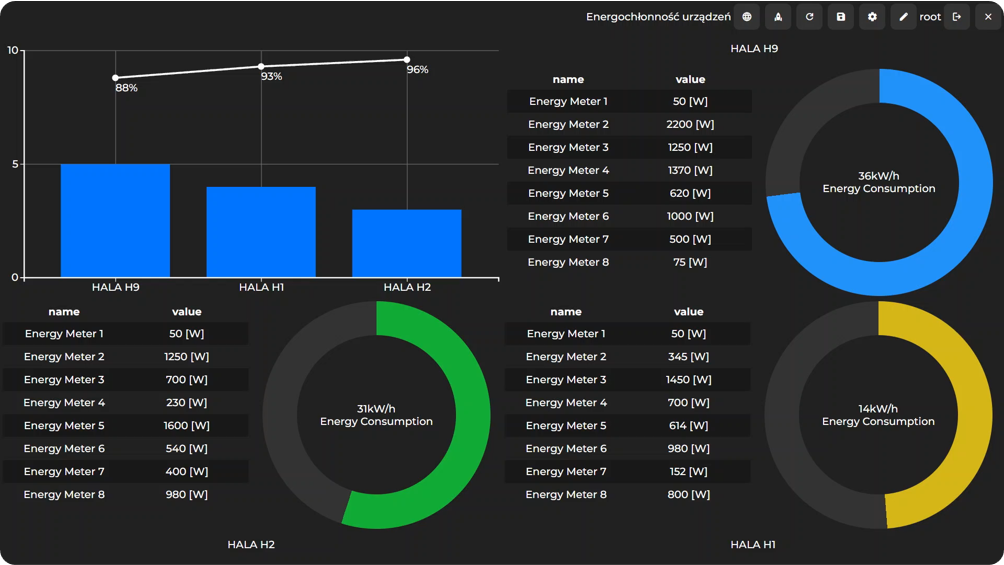

An Energy Management System (EMS) is a module within the explitia Production Portal. It is a tool that supports efficient energy management in production plants. EMS systems are responsible for collecting and visualizing energy consumption data, enabling decision-making based on accurate and reliable analyses.

What are the key benefits of an EMS for your business?

Here are some of the most important features and applications of EMS systems:

- Real-time energy consumption monitoring.

- Identification of high-energy consumption areas.

- Generation of detailed reports on costs and energy efficiency.

- Energy consumption optimization through load balancing.

Dreaming of intelligent energy management? Discover EMS from explitia!

The EMS system from explitia is an advanced tool designed to collect, analyze, and visualize data and other utilities. It offers numerous features that are invaluable in any production facility:

- Integration with energy meters – The explitia EMS provides full visibility into electricity consumption at the level of individual machines, production lines, halls, or entire plants.

- Advanced energy management – The system elevates energy control to a new level, enabling in-depth analysis of consumption and automated report generation.

- Energy consumption optimization – The intelligent energy management system helps identify areas requiring improvements and implement cost-saving solutions.

What are the benefits of implementing an EMS system?

The modern EMS system from explitia is not a standalone application but an integral module of the Production Portal. It can function independently or be easily expanded with other modules like MES, allowing businesses to gradually develop their digital solutions. Simple integration with other systems ensures a comprehensive approach to process analysis and optimization.

Key benefits of EMS implementation:

- Increased Energy Efficiency – energy monitoring systems enable the identification of inefficient processes and optimization of utility management, ultimately enhancing the plant’s energy efficiency.

- Reduction of Operational Costs – by analyzing energy data, companies can reduce consumption and prevent unnecessary losses.

- Improved Energy Flow Management – energy management systems facilitate intelligent control of renewable energy sources and energy storage systems.

- ESG Reporting Support – EMS provides detailed insights into energy consumption, enabling companies to optimize operational costs. Reducing energy usage directly lowers the carbon footprint and positively impacts ESG indicators, helping businesses meet sustainability and environmental regulations.

4 Steps to implementing an EMS system

Step 1: Infrastructure Analysis – Identifying key measurement points and analyzing energy consumption patterns.

Step 2: Selecting the Right Measuring Devices – Choosing energy meters and data concentrators.

Step 3: EMS System Implementation and Configuration – Integrating with existing management systems.

Step 4: Staff Training and Process Optimization – Ensuring effective use of the system in daily operations.

An Energy Management System (EMS) is a flexible tool that can function as a standalone solution or part of a broader production management ecosystem. It is a modern solution for manufacturing companies looking to efficiently manage electricity and utilities. Its implementation leads to optimized energy consumption, lower operational costs, and improved ESG performance. With advanced energy data analysis, businesses can make better decisions and develop sustainable strategies for the future.

Write to us

Are you looking for IT systems for your machine park? Do you want to digitize your plant? Make an appointment for a free consultation!