The benefits of collecting data from machines are indeed numerous, and starting the process of gathering information doesn’t require much. The initial steps necessary for effective and reliable data aggregation were already discussed in our previous article. Today, we will look at the business benefits that these actions bring, along with efficient data analysis supported by appropriate interpretation.

Benefits of Collecting Data from Machines – Work Automation

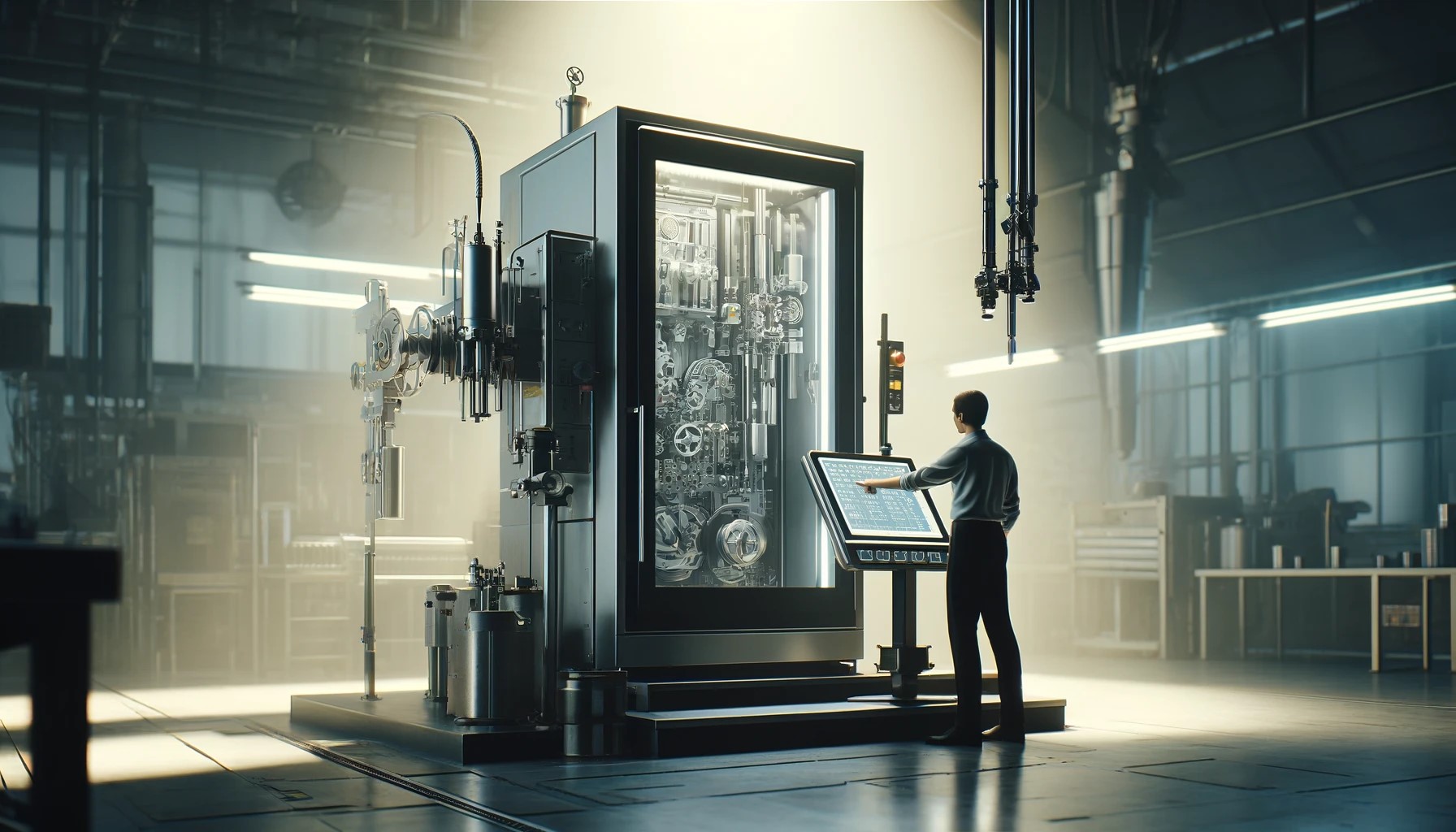

Before implementing a machine data collection automation system, a series of tasks must be performed manually. If we think about a facility employing many operators who collect and document data manually, it’s easy to imagine the space for optimization. The lack of automation in this area usually means a waste of time and human potential, which could be used for more productive activities. Moreover, in some departments, additional work is caused by the need to transcribe the same information, for example, into Excel files and to analyze it independently by a technologist. The goal of automation is to completely eliminate the need for production workers to deal with these tasks.

Minimizing NOK

Systems for collecting data from multiple devices accelerate the response to critical events. Information from the machine is immediately sent in the form of alarms via email messages or SMS. This minimizes the overproduction of NOK-status pieces and their leaving the warehouse. Consequently, it reduces the number of complaints and returns of defective product batches.

Benefits of Collecting Data from Machines – Cost Optimization

Media Consumption in Production

An undeniable advantage of collecting data from machines is the possibility of optimizing manufacturing costs. The integration of systems enables the acquisition of precise knowledge about media consumption – water or energy, for example. Additionally, we can collect information about precise process parameters. Beyond the general OK or NOK status, we also have variables such as temperature, pressure during the process, and even the torque of screws. It’s possible not only to know that a particular piece was defective but, most importantly, why did it happen. Such data is provided in the form of a simple report, illustrated with charts, showing where most errors occur. This makes it possible to quickly eliminate the fault.

Bottlenecks in the production process

Efficient data acquisition also provides information about where bottlenecks occur and how savings can be generated. Here, the Pareto principle, which states that 20% of the effort is responsible for 80% of the outcome, is also applicable.

Determining Real Demand

The integration of systems and collecting data from machines enable the calculation of future demand, for example, for semi-finished products. If statistical data on the demand for products in a specific month are known, the warehouse can be supplied with semi-finished products just before this period. This ensures that the number of components will be sufficient, while at the same time not causing an accumulation of too large quantities of goods in other months.

By implementing a system for aggregating data from machines, you can efficiently start the digitization of your manufacturing plant. The entry threshold is not high. The benefits of collecting data from machines are, however, numerous. If you want to take advantage of this potential – let us know!

Contact us

Do you want to move your production plant to level 4.0? Are you interested in modern solutions for industry in the field of automation and digitisation? Be sure to let us know!