What is an Energy Management System?

EMS (Energy Management System) is a solution designed for efficient energy management in manufacturing plants. It collects, processes, and visualizes energy data, enabling precise and automated tracking of electricity, water, gas, or compressed air consumption. Crucially, it also presents the results in financial terms, factoring in specific tariff rates.

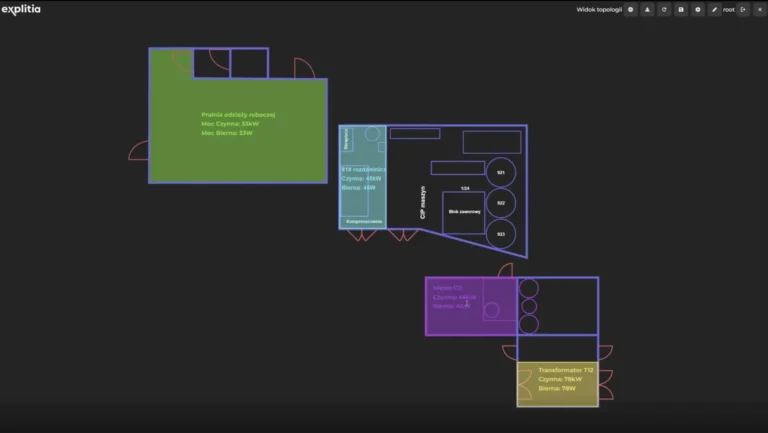

The system can be implemented across any industry and location—wherever there is a need to monitor utility consumption. This includes individual machines, production lines, manufacturing halls, or entire plant buildings. Thanks to advanced analytics and seamless integration with other modules of the Production Portal, explitia EMS not only provides detailed data but also automates the interpretation process, translating technical insights into business-relevant information. This solution can serve as the first step toward implementing a MES (Manufacturing Execution System) in a production facility.

How does explitia's Energy Management System work?

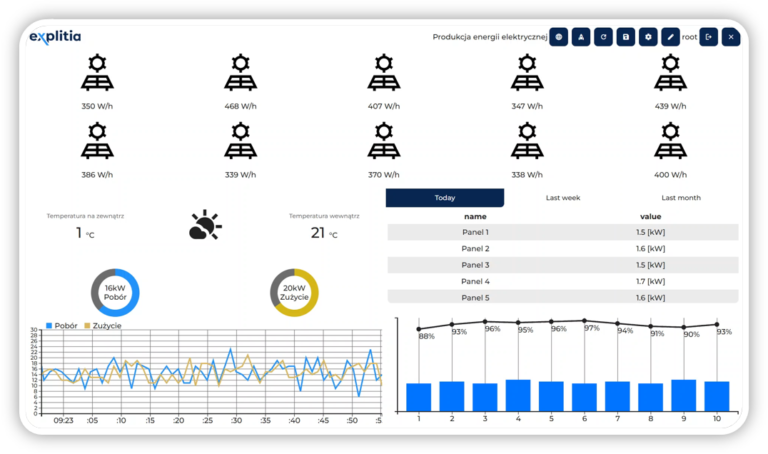

| Data Collection | The system integrates with energy meters, water and gas meters, collecting data in real time. |

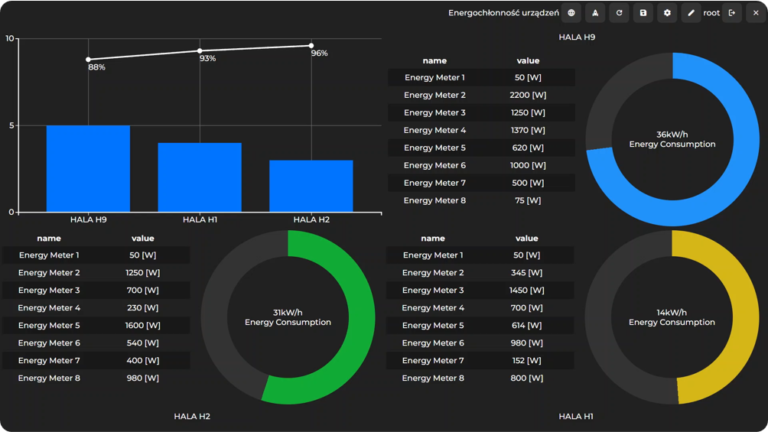

| Analysis and visualization | The data is transformed into clear charts, reports, and alerts, making it easier to identify high-consumption areas. |

| Cost allocation | The system automatically converts energy consumption into costs, factoring in tariff rates, enabling precise allocation of production expenses. |

| Optimization | The EMS enables real-time monitoring and analysis of energy parameters, identifying potential savings. |

| Automated reporting | The system generates ESG reports, facilitating carbon footprint reporting and compliance with sustainability requirements. |

| Loss and anomaly detection | The system can identify excessive energy consumption, such as during downtime or idle operation. It also integrates with SPC (Statistical Process Control) for enhanced process optimization. |

Energy Management System (EMS) integrated with MES

The true value of an Energy Management System (EMS) is realized when integrated with a Manufacturing Execution System (MES). This combination allows for precise cost allocation at the order level—or even down to individual products—within manufacturing execution and traceability systems. With this integration, EMS also automates ESG and carbon footprint reporting while providing deeper insights into production processes.

Get in touch and take control of energy in your business

Want to reduce energy costs and gain full control over utilities in your facility? Contact us—we’ll show you how explitia EMS can boost your savings!

Key differentiators of explitia EMS

- Flexible Data Collection – Collects data from various sources, including electricity, water, gas, and compressed air.

- Automated Reporting – Generates data for your ESG and carbon footprint reports.

- Tariff Management – Precise analysis of energy costs based on real tariff rates.

- Energy Flow Mapping – Detailed visualization of consumption at the level of production lines, machines, or entire plants.

- Integration with Other Systems – Seamless operation with MES for synchronized data and process management.

- explitia EMS is not just a standalone application—it’s a module of the Production Portal. It can serve as the first step in digital transformation, allowing for further expansion with additional solutions.

- The explitia team consists of experienced specialists who can conduct an in-depth analysis and determine, for example, the required communication protocols.

- Web-Based System – No installation required. It operates on a client-server architecture and is fully responsive.

Energy Management System – explitia EMS: More than just electricity costs

Imagine having full control over production costs—not just at the plant level, but down to each individual product. This is exactly what an Energy Management System enables when integrated with MES. This combination allows for precise tracking of energy and resource consumption, assigning them to specific production orders. As a result, you can not only optimize costs but also automate the generation of ESG and carbon footprint reports—effortlessly.

Detect the cost of errors with explitia's Energy Management System

Imagine a situation where a small human error results in an additional machine wash cycle. Sounds harmless? In reality, it leads to increased consumption of water, energy, and chemicals—driving up costs. An Energy Management System detects such events, analyzes their impact, and helps prevent them before they start generating losses. Because true efficiency isn’t just about data—it’s about using it wisely.

Benefits of implementing an Energy Management System – explitia EMS

Precise cost analysis

An Energy Management System does more than just monitor energy consumption—it also translates it into costs. By factoring in tariff rates, it enables precise cost allocation and better energy budget planning. This allows for accurate operational cost assessment and dynamic cost adjustments based on the company’s needs.

Support for ESG and carbon footprint reporting

The system generates comprehensive reports on energy and utility consumption. Data can be exported in various formats, including Excel, making it easy to integrate into corporate reports.

Reduction of operational costs

By analyzing consumption trends, an Energy Management System helps identify and eliminate unnecessary energy losses, leading to potential savings of 10–30%. When combined with the right optimization strategies, businesses can significantly reduce their energy bills.

Cost forecasting capability

An Energy Management System analyzes historical data and forecasts future energy consumption and costs, enabling efficient budget planning and better tariff negotiations with suppliers.

Smart alerts and automated responses

An Energy Management System can be integrated with the SPC module of the Production Portal. In this setup, it not only collects data but also automatically generates alerts when energy consumption exceeds predefined thresholds. Additionally, it enables automated responses to specific events, such as optimizing equipment operation during peak load hours.

Discover how easy It Is to implement an Energy Management System with explitia

Choose explitia’s Energy Management System

It’s not just about data—it’s about interpreting it and turning it into real savings for your facility. explitia EMS is an advanced tool for analyzing and optimizing operational costs, automatically converting utility consumption into actual expenses, identifying anomalies, and supporting ESG reporting.

The explitia team consists of seasoned specialists who will guide your company through the entire implementation process—from technology audits and hardware selection to full system integration. With a well-executed deployment, you’ll achieve measurable results in utility management.

Contact us and take control of your utility consumption

- Looking for an Energy Management System for your machine park?

- Do you want to digitize your facility?