Production Portal – the path to digitization of the cosmetics industry

The cosmetics industry requires a specialized approach to production management and quality control. cosmetics manufacturing must meet the highest standards in terms of both efficiency and ingredient traceability.

To meet these challenges, we created the Production Portal – a modern tool supporting digital transformation in manufacturing companies, including those in the cosmetics industry.

The system is modular and scalable, allowing for gradual implementation of the explitia production portal and its adaptation to the specific needs of chemical plants.

It is web-based, requiring only an internet browser. We ensure full security in compliance with cybersecurity standards and deployment flexibility on both local infrastructure and in the cloud.

Biggest challenges in the cosmetics industry – explitia solutions

1. Production and packaging process efficiency

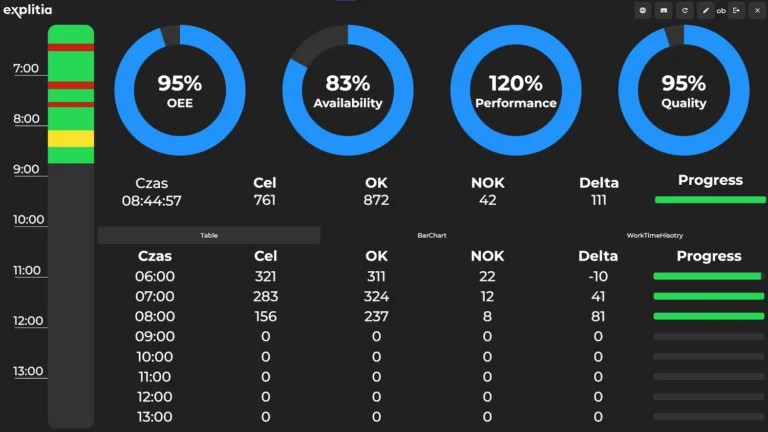

Solution: Efficiency and OEE module

Optimizing cosmetics production is key, especially with frequent line changeovers and varying formulas. Our efficiency module enables:

- Real-time measurement of machine and production line performance.

- Analysis of OEE indicators (availability, performance, quality).

- Identification of downtime causes and production line failures.

- Live monitoring of Pareto charts and hourly production reports.

2. Traceability – full traceability of ingredients and production batches

Solution: Traceability module

In the cosmetics industry, tracking ingredients and production parameters is crucial. Our traceability module provides:

- A detailed record of each batch’s history – from raw materials (e.g., oils, extracts) to the final product.

- Identification of ingredients, raw material batches, and mixing parameters.

- Logging of operators, production lines, and tanks involved in the process.

- Linking specific product batches with quality control results.

3. Maintaining the highest quality with SPC (Statistical Process Control)

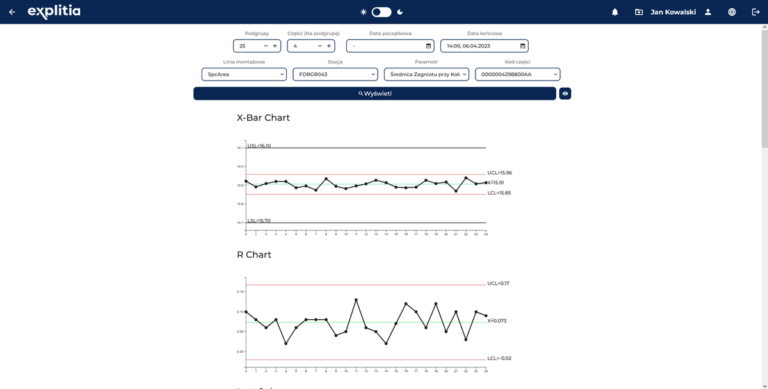

Solution: SPC module

Quality control in the cosmetics industry requires continuous monitoring of production parameters such as blending accuracy, temperature, and dosing precision. Our system enables:

- Real-time automatic statistical process analysis.

- Alert notifications for deviations from production standards.

- Minimization of losses due to defective batches.

- Configurable email and SMS notifications.

4. Flexibility in production planning and execution

Solution: Production planning module

Managing production schedules in cosmetics manufacturing often requires planning production orders based on specific formulas or customer orders. Our planning module offers:

- Dynamic assignment of production orders, considering changeovers and cleaning processes.

- Optimized scheduling based on real-time production data.

- Monitoring of production order execution with fast adaptation to changes.

- Integration with machine data using PLC controllers and IoT devices.

Why implement the Production Portal?

See what you can gain by digitally transforming chemical plants with the production portal.

Scalability

Solutions can be implemented gradually – from a single machine to an entire production line.

Cost optimization

Accurate data on media consumption and process efficiency enable a reduction in operational costs.

Traceability

Full tracking of raw material and finished product batches ensures compliance with regulations and quality standards.

Quick results

The system’s modules deliver measurable benefits within the first few weeks of implementation.

Examples of implementations and our experience in digitization of the cosmetics industry

The Production Portal has been successfully implemented in the food and chemical industries, where production flexibility, quality, and traceability are critical success factors. Our experience allows us to tailor the tool to the specific needs of cosmetics production, providing solutions that meet this industry’s unique requirements.