Whatt is product traceability?

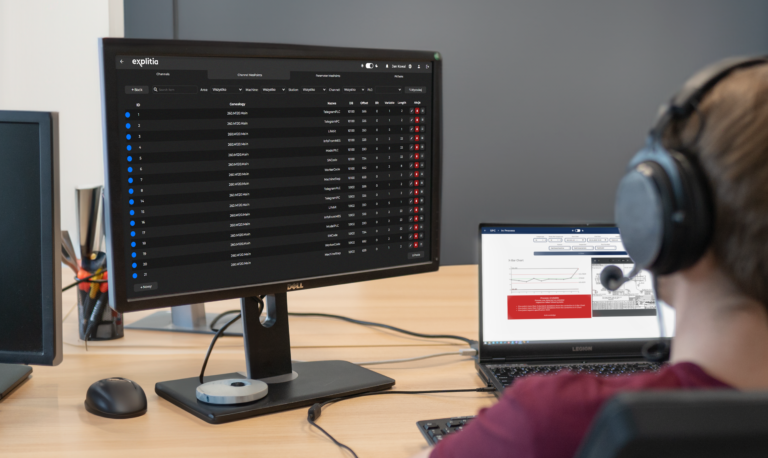

Thanks to modern IT systems, the manufacturer can gain full access to product information and data from the manufacturing process in real time.

Production traceability solutions allow you to control the product both inside the plant and during subsequent storage and transport. Production tracking can therefore be implemented on two levels: internal and external.

Product traceability - what data can be collected

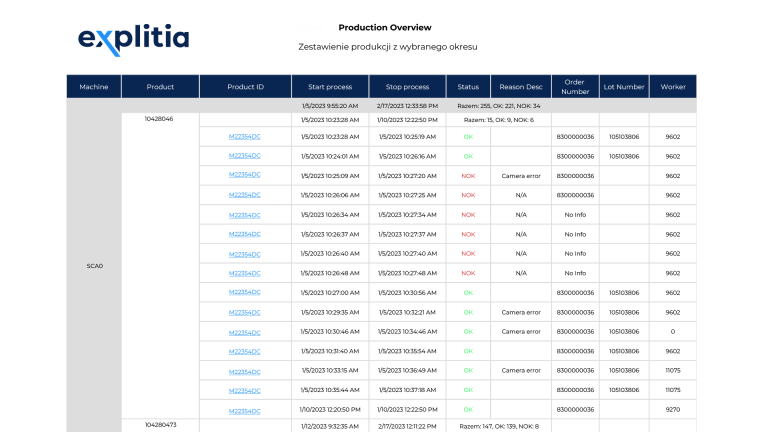

Thanks to traceability systems and the possibility of integrating data from many sources, we can obtain such information as:

- raw materials and components from which a specific product was created,

- materials from which the semi-finished products included in the given product were made,

- producers of specific raw materials,

- the number of products produced under a specific order,

- dates and places of start and end of production,

- data of employees who participated in the production process,

- data of customers who ordered a given product,

- machines that were involved in the production process.

Product genealogy - why is it worth it?

Constant access to information

full insight into the production process helps in efficient analysis and taking action to improve quality and efficiency.

Ability to react quickly

thanks to the data, you can react much more efficiently, e.g. inform customers and wholesalers or withdraw a product from the market.

Compliance with the law

pursuant to Regulation No. 178/2002 of the European Parliament, product traceability is required in enterprises producing food, feed and good that have contact with food, feed and other agricultural products at the level of primary production.

Customer care

traceability of production increases the safety and quality of products. And therefore, it strengthens competitiveness and positively affects the customer’s purchasing decisions.

Sustainable development

traceability of production means transparency in the manufacturing process and supply chain. It has a positive impact on ecological, social and economic aspects.

Product traceability in MES

Production genealogy is one of the elements of the MES class system (Manufacturing Execution System). Depending on the specifics of a given industry, we offer solutions supporting production management and responding to the needs of e.g. mass production and loose or liquid products. However, every company is different and has its own challenges. When implementing solutions in the field of Industry 4.0, we always select tools that will be a real support for a given production plant.

Contact us

Do you want to move your production plant to level 4.0? Are you interested in modern solutions for industry in the field of automation and digitisation? Be sure to let us know!