Automatic reporting - greater efficiency

The automation of the reporting process collects the most important data from the manufacturing process and presents them in the form of clear summaries. All information is historicised and enables efficient analysis and comparison of important indicators. Automatic reporting ensures that the indicated data is correct. This makes it much easier to find the space for optimisation.

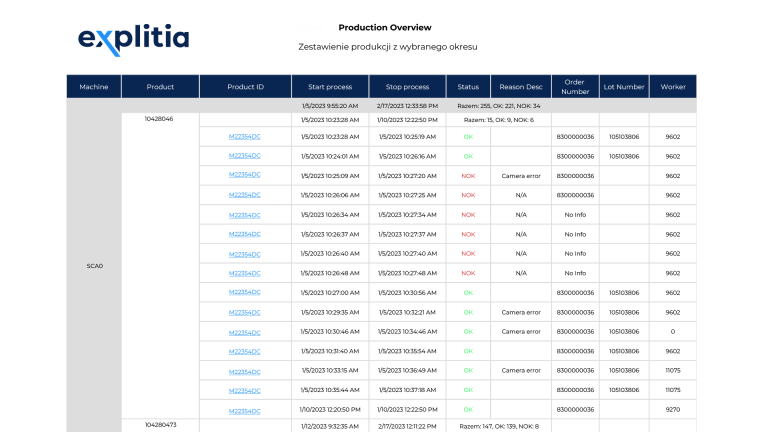

Sample data collected automatically

| Production data and time (start and end dates of the process). |

| Production order number. |

| Operator ID registration. |

| Station ID. |

| Operation number. |

| Registration of process parameters. |

| Identification of the sequence of processes. |

| Registration of product ingredients. |

| Registration of tools used for the product. |

| Operation completion status (OK/NOK). |

| Reason NOK. |

Why is it worth it?

- Ability to diagnose production delays on the machine in real time.

- Full control over the status of production orders in the context of the production plan.

- Access to data and efficiency indicators facilitate optimal production planning.

- Better management of human resources.

- Statistical process control.

- Minimising the risk of errors – the system ensures that the presented data is correct.

- Efficient business and investment decision making – based on real data.

- A way to find bottlenecks and optimise the production process.

- Scalability of the solution – the module can be implemented as a standalone system or in connection with other tools of the Production Portal.

Contact us

Do you want to move your production plant to level 4.0? Are you interested in modern solutions for industry in the field of automation and digitisation? Be sure to let us know!