Gain constant knowledge about OEE

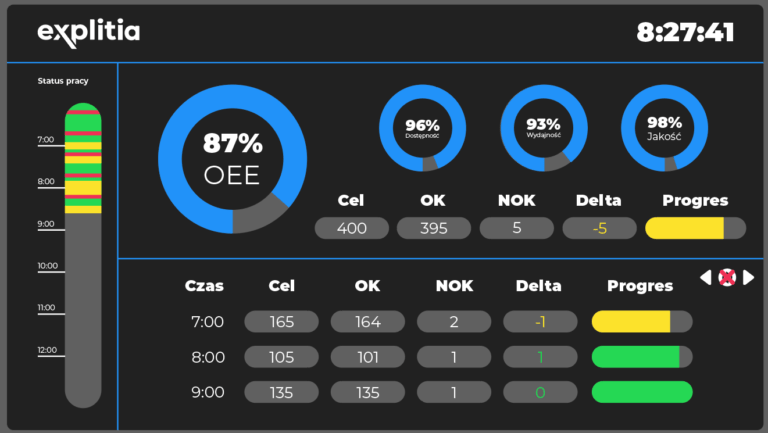

This web application is an ANDON class solution. Thanks to this, while maintaining the highest safety standards, you can gain constant access to OEE and efficiently supervise the production process. Data from the application can work with large-size monitors. One glance enough to learn about the relevant data.

Productivity indicators

Efficiency indicators easily inform about the level of productivity of the entire manufacturing process, as well as of a single workstation. Visualisation of the production status allows you to gain constant insight into current and historical data and indicators. Thanks to automation, the following information is displayed on an ongoing basis:

| The efficiency (OEE) of the operating line. |

| Condition of lines and machines. |

| Quantities produced in the context of a given production order. |

| Production cycle time. |

| Alarm data. |

| Causes of downtime. |

| Process quality information. |

| Readable information hour by hour, providing knowledge about the current state of the production process. It helps in making decisions, e.g. about what should be done to minimise losses and implement the production plan. |

Why is it worth it?

| Support in making business decisions – better communication and the ability to react quickly – real-time insights. |

| Elimination of paper reporting – constant access to reliable data. |

| Saving time, e.g. previously spent on manually entering documents. |

| Lower production costs and higher productivity. |

| Scalability of the solution – the module can be implemented as a standalone system or in connection with other tools of the Production Portal. |

Contact us

Do you want to move your production plant to level 4.0? Are you interested in modern solutions for industry in the field of automation and digitisation? Be sure to let us know!