Environmental aspect

The environmental aspect focuses on how the organization affects our planet. It includes actions to minimize carbon footprint, reduce CO2 emissions and promote recycling. Regardless of the size of the company, the environmental aspect is becoming increasingly important in the face of climate change and is taken into account in investment decisions and consumer choices.

Social aspect

The social aspect focuses on the company’s impact on the local community and its approach to employees. It means caring for the development of people working in the organization and the local economy. Large companies influence the development of infrastructure around them, thus creating additional jobs and activating the local economy.

Management aspect

The management aspect is a matter of building corporate culture and effective communication within the company. The values, vision and mission of the organization should be consistent and understandable to all employees

Challenges of manufacturing companies

Manufacturing companies generate significant amounts of exhaust gases, waste and consume a lot of electricity or gas. These are significant challenges, however advanced measurement and analysis technologies can support optimization.

Production plant and the ESG environmental area

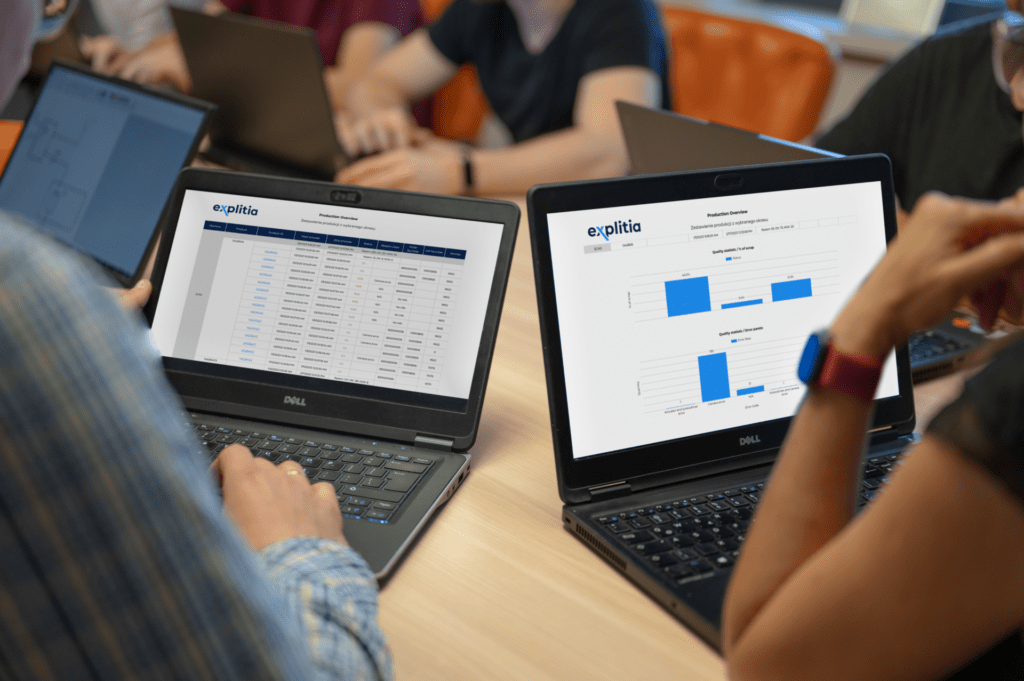

With advanced technology, you can accurately monitor your utility consumption. Effective process documentation and cost optimization require precise data, and the target state of each production should be the level of detail of a product unit.

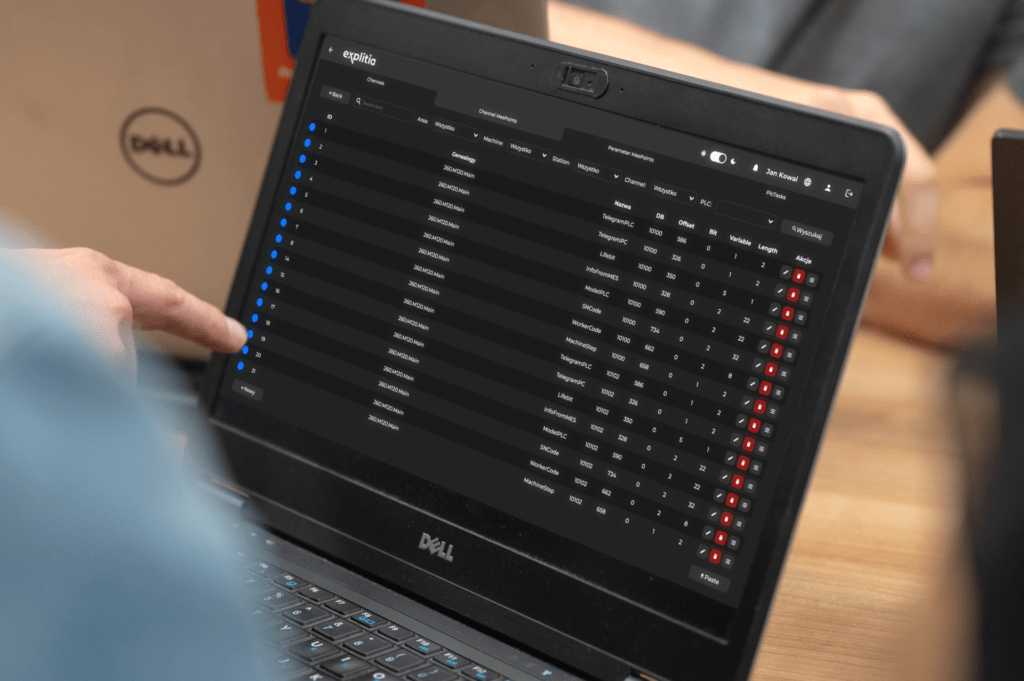

By digitizing the production plant and ensuring proper communication between systems, paper consumption is reduced and the duplication of the same data in different places is limited. Documents are not multiplied, and reliable data automatically goes to the appropriate system, where it is visualized and archived. Modern IT solutions allow you to determine the exact amounts of utilities and raw materials consumed during the production of one cell and analyze the state of current production, as well as identify the causes of any differences.

ESG social area in the production sector

In the social aspect, the IT systems which examine work efficiency and employee satisfaction become helpful. They allow for better use of employees’ potential.

- Systems that automate human work – especially those tasks that are time-consuming and burdensome, and at the same time inefficient – improve the quality and satisfaction of work.

- The digitization of the production plant not only affects the safety and high quality of products, but also makes decision-making processes easier and faster, which in turn increases the comfort and sense of stability of employees and managers.

- Computerization of the reporting and accounting system ensures the reliability of data, additionally reducing the level of employee responsibility as it is taken over by a given tool.

It is important not to lose vigilance and be aware of the need to constantly update the planned actions. Employee and social surveys may also be helpful in this area.

Management of the production plant in accordance with ESG

If you want to implement new technologies, it is worth using the knowledge and experience of independent experts. IT solutions change every couple of months. Therefore, specialist support in updating the planned actions is necessary. An independent advisor will help identify challenges and indicate the best solutions.

Data and ESG-compliant management

With reliable data, the process of making better decisions is significantly improved. It is important that the management board acts coherently with its strategy and informs the entire team about any changes. Transparency and change management are key to aligning the values of employees and the company. High-quality technology consulting can also help in this area – it will show employees the real benefits of introducing changes.

Even though management aspects are much more difficult to measure, it is worthwhile to introduce activities such as surveys or personal conversations into the company’s daily life to increase the effectiveness of communication and improve employee morale.

ESG in the machinery park – how to start?

1. Conducting an audit and analyzing the AS IS situation

The analysis of the current situation may not be fully effective if it is carried out only in-house. When mapping AS IS circumstances and implementing new IT systems, the presence of an independent external specialist may be extremely helpful.

2. Settlement with the reality of the plant

After receiving the audit results, it is worthwhile to perform a self-assessment and decide whether the current situation is acceptable or requires improvement.

3. Building a map of digital transformation and a new ESG strategy

How long do the first steps in ESG take?

The time largely depends on the size of the plant. Large enterprises with a dispersed structure, many factories and thousands of employees will undergo a prolonged process. In a medium-sized production plant, explitia is able to complete three basic transformation steps within 1 to 3 months.

However, implementing an ESG strategy is not a process that has a clearly defined beginning and end. Sustainable development actions must become part of an organizational culture that is constantly ongoing and developing.

ESG in a manufacturing company and costs

The introduction of an ESG strategy carries certain costs, but above all it brings long-term benefits. Therefore, ESG should not be considered in terms of price, but in terms of investment in reducing production costs, increasing employee and customer satisfaction, increasing sales and improving the company’s image.

The entire process should come down to realizing what the costs of individual investments are, and above all, what the returns on these investments are. It is also worthwhile to look at a kind of score that will answer in how many aspects the investment will actually change the company.

ESG in a manufacturing company – examples of activities

| Utility metering - implementing a system that not only collects data, but also analyzes it and provides conclusions, thus providing information about areas which require optimization. |

| Automation of tasks and better use of human resources. |

| Robotization of dangerous workstations. |

| Rewarding employees on the basis of performance measurement for better results than the standard ones. |

| Providing training and courses. |

| Consistent communication and up-to-date information about what is happening in the company. |

| Funding to local infrastructure. |

Contact us

Do you want to move your production plant to level 4.0? Are you interested in modern solutions for industry in the field of automation and digitisation? Be sure to let us know!